| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Make | CBRO |

| Model | CMF250-20 |

| Click to view more | |

Product Details

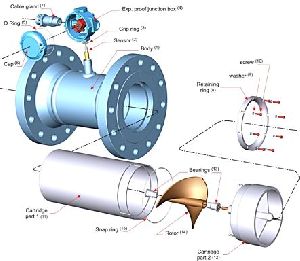

CMF250-20 Series Coriolis mass flow meter is designed according to micro motion and Coriolis principle. It is a leading precision flow and density measurement solution offering .

The Coriolis flow meter worked on the Coriolis effect and was named. Coriolis flow meters are considered to be true mass flow meters because they tend to measure mass flow directly, while other flow meter techniques measure volume flow.

Advantages :-

Coriolis Type Flow Meter Advantages

It has high measurement accuracy, standard accuracy 0.2%; And the measurement is not affected by the physical properties of the medium.

Coriolis type flow meter provide a direct mass flow measurement without the addition of external measurement instruments. While the volumetric flow rate of the fluid will vary with changes in density, the mass flow rate of fluid is independent changes.

Flow meters are operated by flow characteristics such as turbulence and flow distribution. Therefore, upstream and downstream direct pipe operating flow regulation requirements are not required.

Application :-

● Petroleum, such as crude oil, coal slurry, lubricant and other fuels.

● High viscosity materials, such as asphalt, heavy oil and grease;

● Suspended and solid particulate matter materials, such as cement slurry and lime slurry;

● Easy-to-solidified materials, such as asphalt

● Accurate measurement of medium- and high-pressure gases, such as CNG oil and gas

● Micro-flow measurements, such as fine chemical and pharmaceutical industries;

Installation :-

Coriolis Mass Flow Meter Installation

1. Basic Requirements on installation

(1)Flow direction should be in accordance with PHCMF sensor flow arrow.

(2)Properly supporting is required for preventing tubes vibrating.

(3)If a strong pipeline vibration is inevitable, it is recommended to use a flexible tube to isolate the sensor from the pipe.

(4)Flanges should be kept parallel and their center points should be located on the same axis to avoid subsidiary force generation.

(5)Installation vertically, make the flow from the bottom up when measuring, meanwhile, the meter should not be installed on the top to prevent air getting trapped inside the tubes.

2.Installation Direction

In order to ensure the reliability of the measurement, the ways of installation should consider the following factors

Raise your Query

Hi! Simply click below and type your query.

Our experts will reply you very soon.