Flow Meter

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Ultrasonic Flow Meter, Electromagnetic Flow Meters, Oval Gear Flow Meter, Vortex Flow Meters, Turbine Flow Meters, Thermal Mass Flow Meters, Steam Flow Meter, Helical Flow Meter, Paddle Wheel Flow Meter and Coriolis Mass Flow Meter from Thane.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Automatic Grade | Automatic |

| Application | Industrial |

CBRO UFM250H portable clamp-on Ultrasonic Flowmeter is one of the most powerful Flowmeters available for liquid measurement. The utilisation of our ultrasonic signal processing, transit-time measurement and signal quality tracking technologies allow the Flowmeter to measure liquid flow rate from outside of a pipe reliably and accurately.

The Flowmeter is carefully designed, so that it is very compact and easy to use. A user can use hand to hold as well as to operate the Flowmeter main unit. The user-interface is self-explanatory and very easy to follow. Besides, the unique clamp-on fixture design makes the installation very simple and no special skills or tools required. Due to the non-intrusive nature of the clamp-on technique, there is no pressure drop, no moving parts, no leaks and no contamination.

Salient Features:

- Cost effective and versatile

- High accuracy 1.0% reading

- Non invasive, no moving parts, no pressure drop, no maintenance

- Easy and economical installation, no pipe cutting

- Wide measurement range 0 ~ 12m/s

- Wide pipe size range (DN 15 ~ 4570mm)

- Suitable for all commonly used pipe materials

- Bi-directional measurement. Totaliser display for net, positive and negative flow

- Ideal for both clean and opaque liquid flow measurement

Applications:

- Chemical, petrochemical and process Industries

- Fertilizers industries

- Pharmaceutical industries

- Food and drug industries

- Sugar, beverage industries

- Paper and pulp industries

- Water and waste water management

- Dredging industries

- Mining industries

| Business Type | Manufacturer, Exporter, Supplier |

| Make | CBRO |

| Model | DIGIMAG250 |

| Nominal dia (mm) | 10 to 3000 |

| Working pressure (kg/cm2) | 10, 16, 25, 40 |

| Working temperature | Integral PTFE – 120oC Remote PTFE – 180oC Others – 70oC |

| Electrode material | SS 316L Std.* |

| Sensor lining | Std. Rubber* |

| Display version | Integral/Remote |

| Measuring tube material | SS 304 Std.* |

| Sensor housing material | Std. CS* |

| End connection | Flange/Wafer/Tri-clamp/SMS |

| Flange standard | ANSI 150* |

| Measuring range | 0.2 to 12 m/sec. Bidirectional |

| Accuracy % of measured value | ±O.5% (±O.2% consult factory) |

| Repeatability | ±0.2% of Span |

| Display | 2 line LCD |

| Display units | All standard engineering units in m3, litre, gallon, ft3, imperial gallon |

| Output | Std. 4 – 20 mA* |

| Power supply | 12 – 60 V DC or 80 – 300 V AC/DC Solar powered |

| Protection class for sensor | Std. IP 65 Option IP 67/IP 68 for flow tube in remote type |

| Protection class for transmitter | IP 67 |

| Cable length for remote | Std. 10 m* |

| Installation | Inline flanged type |

| Note | For options please refer to order code from catalogue |

Electromagnetic flow measurement has been in use around the world for 50 years and more, as witnessed by the popularity of these meters that continues unabated in virtually all sectors of industry. Electromagnetic Flowmeters can be used to measure all electrically conductive liquids (> 5 µS/cm) with or without solids, e.g. water, wastewater, sludge, slurries, pastes, acids, alkalis, juices, fruit pulp, etc.

CBRO DIGIMAG250 Full Bore Electromagnetic Flowmeter is suitable for the most demanding applications. It is based on Faraday’s law of Electromagnetic Induction. The meter features flanged construction and is available with choice of liner and electrode material. All meters consist of a sensor and a converter that may be mounted either integral to the sensor or remotely with a field mount kit. CBRO Flowmeters are calibrated at our own Water Flow Calibration Facility. It uses the primary method of measuring the water flow by gravimetric principle. The facility is designed for calibration of flowmeters under controlled and stable flow conditions.

Salient Features:

- Based on Faraday’s law of electromagnetic induction

- Flow tube sizes 10 mm to 3000 mm and above

- Coil assembly in hermetically sealed welded construction

- Integral or remote transmitter

- Field interchangeable electronics

- High linearity due to characteristic magnetic field

- Absolute zero stability and noise elimination due pulsed DC excitation

- High long-term stability and reliability

Applications:

- Chemical, petrochemical and process industries

- Fertilizers industries

- Pharmaceutical industries

- Food and drug industries

- Sugar, beverage industries

- Paper and pulp industries

- Water and waste water management

- Dredging industries

- Mining industries

| Business Type | Manufacturer, Exporter, Supplier |

| Brand | CBRO |

CBRO OGF - 250M Oval gear Flow Meter the mechanical type positive diaplacement flow meter is used is a wide variety of applications including measuring of boiler fuel oil and diesel oil, as well as transactions of kerosene, light oil & heavy oil.

OGF - 250M return - zero oval gear flow meter adopts the zero - returnable counter added to the basic model. The counter contains two groups of digit wheels-one for zero returning and the other for accumulation to undertake the cumulate and batch counter respectively.

OGF-250M-A cast Iron oval gear flow meter is widely applicable to metering various oils and fluids that effects no corrosion on cast iron.

OGF-250M-E cast steel oval gear flow meter is designed for metering a variety of high-pressure, Low corrosion fluids.

- Uniform rotator, small vibration, long working life.

- Low sensitivity to variance of viscosity, suitable applied in be high viscosity liquid.

- Simple instructions, small sizes, light weight,

- Simple installation, no need to install straight pipe section before meter

Applications:

- Lubricatinng Oil

- Epoxies

- Fuels Storage Tank Flow Meter

- Oil Counter

- Tank Truck Flow Meter

- High Accurycy, Wide Range

- Mechanical Display

- Easy Maintenance

- Easy to Read

- Output 4-20ma Profibus

| Business Type | Manufacturer, Exporter, Supplier |

| Make | CBRO |

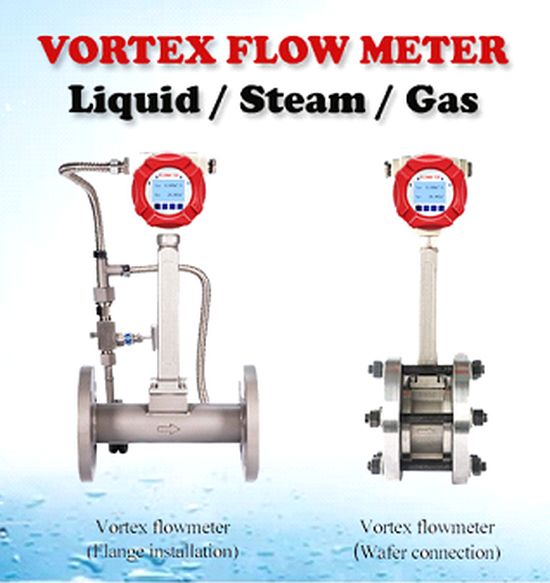

| Model | VFM250 |

| VFM250 | Liquid / Gas / Steam |

| Diameter | 10,15,20,25,32,40,50,65,80,100,150,250,300,(300~1000) |

| Temperature | Piezoelectric:-40~60ºC Capacitive:-40~300ºC |

| Material | Stainless steel material |

| Vibration Acceleration | Piezoelectric:0.2g Capacitive:1.0~2.0g |

| Accuracy | 1.0%FS;1.5%FS; Insert type:2.5%FS |

| Flow ratio | 1:6~1:30 |

| Power supply | Flow Sensor:12VDC/24VDC / Battery: 3.6V |

| Output | Pulse ,4~20mA Output ; Battery supply can not provide any output |

| Explosion | ExdIIia CT2~T5 or ExdII CT2~CT5 |

| Protection | IP65 or IP68 |

CBRO vortex flowmeter is used for measuring the flow velocity of gases or liquids in pipelines flowing full. The measuring principle is based on the development of a Karman vortex shedding street in the wake of a body built into the pipeline. The periodic shedding of eddies occurs first from one side and then from the other side of a bluff body (vortex-shedding body) installed perpendicular to the pipe axis. Vortex shedding generates a so called "Karman vortex street" with alternating pressure conditions whose frequency is proportional to the flow velocity.

Features:

- Lattice LCD display

- Easy operation

- Configure with temperature/pressure senor. For temperature sensors, Pt100 or Pt1000; For pressure sensor, gauge pressure sensor or absolute pressure sensor

- Multiple Outputs can be optional: Two-Wire 4-20mA, Three-Wire pulse and Three-Wire equivalent output

- Excellent nonlinearity correction function, greatly improve the appearance of linearity

- Spectral analysis, improve the ability of anti-interference and vibration resistance

- A variety of measuring medium: vapor, liquid, gas and natural gas, etc.

- Low power consumption, a dry cell can maintain at least 3 years

- Automatic switching ability of the working modes: Battery supply, Two-Wire and Three-Wire

- Self-checking function: the rich self-checking information make easy maintenance and debugging

- Independent password setup, the parameters setup, total flow reset and calibration can be set with different- level passwords, it is convenient for management

- Three-Wire system supports RS485 communication The display unit can be selected and user-defined

| Business Type | Manufacturer, Exporter, Supplier |

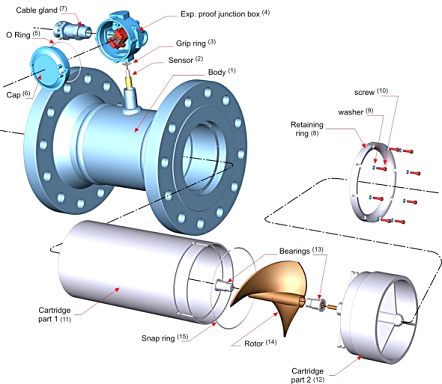

| Line Size | 6 NB to 250 NB |

| Measuring Range | 0.18 to 750 m3/hr of water / clear liquid 0.5 to 2200 Nm3/hr of Air/Gas at NTP |

| Display | 4 Digit LED for flow rate & 8 Digit LED for totaliser |

| Transmitter Electronics | Integral / Remote |

| Accuracy | +1- 1% F.S. (0.5% Optional) |

| Linearity | +/-0.5% |

| Repeatability | +/-0.2% |

| Turn down ratio | 10 : 1 to 100 : 1 |

| Density / Sp. Gravity | Up to 2.95 |

| Viscousity | Up to 100 cp |

| Process Temperature | 0-80 Deg C (Special design for high temerature available) |

| Process Pressure | 0-20 Kg/cm2 (Special design for high pressure available) |

| Material of construction | Bearings Tungsten Carbide Sleeve / Rotor ½ SS 410 |

| Power Supply | 24 V DC, External / Battery Powered / Solar Powered |

| Power Consumption | < 1 VA |

| Response Time | < 100 m Sec |

| Temperature Coefficient | +/-0.01 % per 0C |

| Transmitter Enclosure | Flame-proof, IP-65, IIA, IIB CMRI certified |

| Mounting | Flush of Panel |

| Communication | RS485 Modbus / GPRS / Wifi |

| Series | TFM250 |

CBRO make TFM250 series Turbine Flow Meter are designed for the volumetric measurements of liquids & gases. The meters are rugged, reliable & precise instruments suitable for all industrial corrosive & Non – Corrosive Chemicals, Fuels, and Oil & Gases etc. The basic meter consists of a freely suspended bladed rotor positioned axially in the flow stream with the flowing fluid pushing against the blades. The rotational speed of the turbine is proportional to the velocity of the fluid & hence truly represents the volume of the fluid flowing through meter. The rotation of turbine rotor generates electrical pulses in the pick off attached to flow meter housing. The output pulses are amplified & converted to measure flow rate & integration. Turbine sensor with four/six digit batch controller with ICO Relay output contact offered to transfer. Preset qty. Of liquid from main storage tank with automatic flow shut off. We are a credible Manufacturer, Exporter and Supplier of Turbine Flow Meter in India.

Applications:

- Water

- Diesel

- Petrol

- Vegetable Oil

- Hydraulic Oil

- Chemical (S.S. With Teflon coating)

- Milk plant.

- Air

- Gases

| Business Type | Manufacturer, Exporter, Supplier |

| Display | 4 lines LCD Mass flow, Volume flow in standard condition, Flow totalizer, Date and Time, Working tim |

| Accuracy | +/-1~2.5% |

| Country of Origin | India |

| Material | Stainless Steel |

| Finishing | Chrome Finish |

| Pressure | Medium Pressure |

| Usage | Industrial |

| Make | CBRO |

| Model | TMF1600 Series |

| Measuring Medium | Various Of Gas (Except Acetylene) |

| Pipe Size | (Insert connection) DN50-DN2000mm ,In-line connection(DN10-DN2000mm) |

| Velocity | 0.1-100Nm/s |

| Working Temperature | Sensor:-40~+220 degC Transmitter:-20~+45 degC |

| Working Pressure | Insertion Sensor:medium pressure ≤1.6Mpa Flanged Sensor:medium pressure ≤4.0Mpa Special pressure ple |

| Power Supply | Compact type: 24VDC or 220VAC, Power consumption ≤18W Remote type:220VAC,Power consumption ≤19W |

| Response Time | 1s |

| Output | 4-20mA(optoelectronic isolation,maximum load 500Ω),Pulse RS485(optoelectronic isolation) and HART |

| Alarm Output | 1-2 line Relay, Normally Open state, 10A/220V/AC or 5A/30V/DC |

| Sensor Type | Standard Insertion, Hot-tapped Insertion and Flanged |

| Construction | Compact and Remote |

| Pipe Material | Carbon Steel, Stainless Steel,Plastic etc. |

| Protection | IP65 |

Flange thermal gas mass flow meter is one of kind mass flow meter which Is popular in industrial applications is the way they are designed and built. The feature is no moving parts, nearly unobstructed straight through flow path, require no temperature or pressure corrections and retain accuracy over a wide range of flow rates. Straight pipe runs can be reduced by using dual-plate flow conditioning elements and installation is very simple with minimal pipe intrusions. Flange thermal gas mass flow meter size from DN10~DN2000mm

Advantages :-

Flange thermal gas mass flow meter advantanges :

(1)Wide range ratio 1000:1;

(2)Large diameter, low flow rate, negligible pressure loss;

(3)Direct mass flow measurement without temperature and pressure compensation;

(4)Very sensitive for low flow rate measurement;

(5)Easy to design and select, easy to install and use;

(6)Suitable for all kinds of single or mixed gas flow measurement Could measure gas with flow velocity from 100Nm/s to 0.1Nm/s, which can be used for gas leak detection;

(7) No pressure loss or very small pressure loss.

Application :-

Flange thermal gas mass flow meter application:

Thermal gas air flow meter widely use for Electric power, Petrochemical industry, Glass, Ceramics and Building materials industry, and mainly be used to meausre Dry gas, such as Air, Natural gas, LPG gas, Biogas, ect. But thermal gas mass flow couldn’d be used to measure Vapour, Humidity gas and Ethyne.

Installation :-

nge thermal gas mass flow meter installation:

① Observe the recommended inlet and outlet requirements.

② Good engineering practice is necessary for the associated pipe work and installation.

③ Ensure correct alignment and orientation of the sensor.

④ Take measures to reduce or avoid condensation (e.g. install a condensation trap, thermal insulation, etc.).

⑤ The maximum permitted ambient temperatures and the medium temperature range must be observed.

⑥ Install the transmitter in a shaded location or use a protective sun shield.

⑦ For mechanical reasons, and in order to protect the pipe, it is advisable to support heavy sensors.

⑧ No installation in where large vibration exists

⑨ No exposure in the environment containing a lot of corrosive gas

⑩ No sharing power supply with frequency converter, electric welding machine and other machines which can make power-line interference.

Daily maintenance for flange thermal gas mass flow meter:

In the daily operation of the thermal gas mass flowmeter, check and clean the flowmeter, tighten the loose parts, find and deal with the abnormality of the flowmeter in operation in time, ensure the normal operation of the flowmeter, reduce and delay the wear of components, Extend the service life of the flowmeter. Some flowmeters will become fouling after being used for a period of time, and it must be cleaned by pickling etc. depending on the degree of fouling

| Business Type | Manufacturer, Exporter, Supplier |

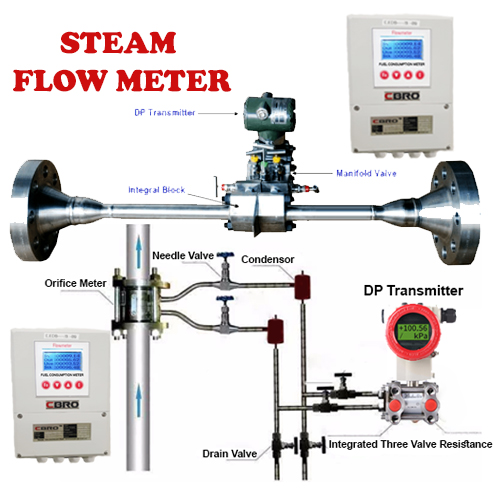

| Make | CBRO |

| Model Name/Number | SFM250 |

| Service | Saturated and superheated steam, hot water, thermic fluids in closed pipes |

| MOC of flanges | MS |

| Orifice flange assembly | WNRF class 300 |

| DPT | With display |

| Data logging | 3450 readings or 6900 readings (Optional) |

| Comm port | RS485 |

| Comm Protocol | RS232/485 Modbus Protocol |

| Typical turndown | 103 (Std) |

| Density compensation | Online monitoring and compensation of density |

| Pressure | 22 kg/cm2 Max |

| Size | Max 10 inch |

| Type of flow element | Orifice type |

| MOC of flow element | SS 316 |

| End connection | Sorf flange |

The SFMc-150 flow meter is applicable for measuring flow rates of saturated and superheated steam, mass flow rates of Boiler feed Water in closed conduits. It is best suited for applications where affordability, reliability and ruggedness are of prime concerns.

It can be used as heat energy transfer meter to measure thermal energy using various fluids which are being used as the heat transfer medium.

In the conventional system of measurement, the differential pressure generated by orifice plate is measured by DP transmitter. The output from DP transmitter after square rooting is accepted as proportional to flow rate. This assumption is true only when the density is constant. Unfortunately, the density of the compressible fluid is never constant. The density of compressible fluid changes with line pressure and line temperature. Thus, introducing errors in flow rate measurement.

Features of Steam Flow Meter:

- Easy user-friendly programming

- Password protected for all modes except display mode

- Computer/Printer Interfacing with RS 232/RS 485 port with MODBUS RTU

- Fault indication indicated by different error codes

- Overflow indicated by blinking display up to 3000 readings (for more readings consult factory)

- Data logging facility with 3450/ 6900 number of reading is available

- Linear or square root operation

- Universal power supply

- Suitable for Saturated &/or Superheated Steam

- Two-alarm setting configured on pressure input

- Steam status indication (Saturated/ Superheated)

- Pressure and temperature offsets generated by site condition can be compensated

- Mass flow calculation as per ASME algorithm

| Business Type | Manufacturer, Supplier |

| Make | CBRO |

| Model | HTFM250 |

| Display | Digital |

| Size | 25 to 300mm |

| Process temperature | 150 Degree C |

| Operating pressure | 5800 psig (400 bar) max. |

| Flow rates | +/-0.10% |

| Viscosities | 30 up to 1,000,000 cSt (below 30 cSt with restricted measuring range and vertical mounting) |

| Linearity | +/-0.50% of actual flow value (from 30 mm2/s up)+/-0.25% of actual flow value (from 100 mm2/s up) |

| Supply Voltage VB | +8.5 up to 29 VDC,regulated; 5 mA current draw |

| Frequency Range | 2 up to 4,000 Hz |

| Housing | IP 65,aluminum AlMgSiPb,blue anodized |

| Power Supply | 24 VDC / 230 VAC / Battery Powered / Solar Powered |

| Output | Pulse / 4-20mA |

| Communication | RS485 Modbus / GPRS / Wifi |

Benefits:

- Affordable and Accurate: This meter has the ability to maintain consistent accuracy despite changing viscosity conditions, with accuracy of ±0.5% of reading.

- Rugged Construction: The CBRO solid meter construction is made of stainless steel with tungsten carbide bearings for corrosion resistance and durability Optional hard-coat gear offerings available.

- Flexible: May be used with a wide range of materials and viscosities with a low pressure drop than conventional meters and wide flow range/size selection.

- Proven Reliability & Performance: With a proven industry record for reliable meter life and electronics, these meters are ready to be installed into your process today.

Applications:

This series of flow meters from CBRO is a high-resolution answer to your metering needs. Made of stainless steel, the meters in the HTFM series offer wide measuring ranges and low pressure loss. A helical-gear design gives these meters lower pressure drop compared to other meters and ideal for metering high viscosity polyurethanes, polymers, glues, sealants, and heavy fuel oils.

CBRO offers these specialized helical gear flow meters suitable for a variety of industrial application,

including:

- Sealant / Adhesive Dispensing Applications – Single And Multi-component

- Paint Reclaim And Environmental Tracking

- Paint Circulation / Supply

- Paint Spray Operations-high Solids / Filled Materials

- Material Manufacturing – Monitoring / Batching

- Rim Applications

- Polyurethane And Polymer

- Light And Heavy Fuel Oil

- Petrochemical Products

- Thixotropical Fluids

- Crude Oil

- Fuel Oil

- Fat And Oils With Varying Viscosities

- Hydraulic Test Rigs With Varying Viscosities And Fluids

- Water / Glycol Mixtures

- Furnace Oil and all viscous liquid even viscosity change with temp

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CBRO |

| Country of Origin | India |

| MODEL | PWF250 Series |

| Type | Paddle Wheel Flow Meter |

| Feature | High Accuracy, Robust Design, Easy Installation, Line Size From 25 NB, 4-20 MA Output, RS485 Modbus |

| Application | Chemical Industries, Pharmaceutical Industries, Food & Sugar Industries, Textile Industries, Ceramic Industries, Paper Mills, Industrial R.O., Water Supply Schemes,Volumetric Total Flow And/or Flow Rate Measurement |

| Modes | Indicator & Totalizer, Batcher, Flow Comparator, Rate Switch Mode, Pulser, Dual Totalizer |

| Additional Info | 6 Different Modes Available For Wide Application |

Paddle Wheel Flow Meter, which is easy to operate and gives accurate and reliable measuring of flow. The flow and the revolutions of the paddle wheel are proportional to each other. Thus, by spinning the paddle wheel with the force from the flowing fluid, it becomes possible to measure the rate of this flow from the number of revolutions. A paddle wheel flow meter is used for volumetric total flow and/or flow rate measurement since it has a relatively simple working principle. When fluid flows through the turbine meter, it impinges upon turbine blades that are free to rotate about an axis along the center line of the turbine housing. The angular (rotational) velocity of the turbine rotor is directly proportional to the fluid velocity flowing through the turbine.

Features:-

- High Accuracy in Low cost

- Robust Design

- Easy Installation

- Line Size from 25 NB

- Wide application because it has 6 different modes.

- 4-20 mA output

- RS485 Modbus

Application

- Chemical Industries/ Pharmaceutical Industries

- Food & Sugar Industries

- Textile Industries

- Ceramic Industries/ Paper Mills

- Industrial R.O. /Water supply schemes

Various Modes :-

- Indicator & Totalizer : The meter is in flow indication mode with showing totalizer in display in order to monitor current flow.

- Batcher : Relay will energize after a pressing start button and remains energized till fixed quantity of liquid passes through the sensor. The batcher has a halt and reject batch function.

- Flow Comparator : The meter has two sensors for permeate and reject line. The meter displays both the flow rates and calculates percentage recovery also gives alarm on reducing rate of recovery.

- Rate Switch Mode : The relay has programmed a way to get energize whenever actual flow falls/rise the set value. Display shows “LOW/HIGH FLOW RATE”. Ideal f or flow interlock, chemical dosing.

- Pulser : To operate specific task on completion of prefix volume. Meter can configure to any metering /dosing pump.

- Dual Totalizer: It’s a 2nd totalizer. It can be used regardless of totalizer 1 settings.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Make | CBRO |

| Model | CMF250-20 |

| Flow Accuracy | ±0.2% Optional ±0.1% |

| Diameter | DN3~DN200mm |

| Flow repeatability | ±0.1~0.2% |

| Density measuring | 0.3~3.000g/cm3 |

| Density accuracy | ±0.002g/cm3 |

| Temperature measuring range | -200~300℃ (Standard Model -50~200℃) |

| Temperature accuracy | +/-1℃ |

| Output of current loop | 4~20mA; Optional signal of flow rate/Density/Temperature |

| Output of frequency/pulse | 0~10000HZ; Flow signal (Open collector) |

| Communication | RS485, MODBUS protocol |

| Power supply of transmitter | 18~36VDC power≤7W or 85~265VDC power 10W |

| Protection class | IP67 |

| Material | Measuring tube SS316L housing:SS304 |

| Pressure rating | 4.0Mpa (Standard pressure) |

| Explosion-proof | Exd(ia) IIC T6Gb |

| Ambient temperature | -20~-60℃ |

| Enviroment humidity | ≤90%RH |

CMF250-20 Series Coriolis mass flow meter is designed according to micro motion and Coriolis principle. It is a leading precision flow and density measurement solution offering .

The Coriolis flow meter worked on the Coriolis effect and was named. Coriolis flow meters are considered to be true mass flow meters because they tend to measure mass flow directly, while other flow meter techniques measure volume flow.

Advantages :-

Coriolis Type Flow Meter Advantages

It has high measurement accuracy, standard accuracy 0.2%; And the measurement is not affected by the physical properties of the medium.

Coriolis type flow meter provide a direct mass flow measurement without the addition of external measurement instruments. While the volumetric flow rate of the fluid will vary with changes in density, the mass flow rate of fluid is independent changes.

Flow meters are operated by flow characteristics such as turbulence and flow distribution. Therefore, upstream and downstream direct pipe operating flow regulation requirements are not required.

Application :-

● Petroleum, such as crude oil, coal slurry, lubricant and other fuels.

● High viscosity materials, such as asphalt, heavy oil and grease;

● Suspended and solid particulate matter materials, such as cement slurry and lime slurry;

● Easy-to-solidified materials, such as asphalt

● Accurate measurement of medium- and high-pressure gases, such as CNG oil and gas

● Micro-flow measurements, such as fine chemical and pharmaceutical industries;

Installation :-

Coriolis Mass Flow Meter Installation

1. Basic Requirements on installation

(1)Flow direction should be in accordance with PHCMF sensor flow arrow.

(2)Properly supporting is required for preventing tubes vibrating.

(3)If a strong pipeline vibration is inevitable, it is recommended to use a flexible tube to isolate the sensor from the pipe.

(4)Flanges should be kept parallel and their center points should be located on the same axis to avoid subsidiary force generation.

(5)Installation vertically, make the flow from the bottom up when measuring, meanwhile, the meter should not be installed on the top to prevent air getting trapped inside the tubes.

2.Installation Direction

In order to ensure the reliability of the measurement, the ways of installation should consider the following factors