Ultrasonic Flow Meter

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Clamp On Wall Mounted Ultrasonic Flow Meter, Handheld Ultrasonic Flow Meter, Integral Display Flange Ultrasonic Flow Meter, Modular Type Ultrasonic Flow Meter, Open Channel Flow Meter, Portable Ultrasonic Flow Meter, Ultrasonic Flow Meter In-line Type, Ultrasonic Water Meter With Amr System and Wall mounted Insertion Ultrasonic Flow Meter from Thane.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CBRO |

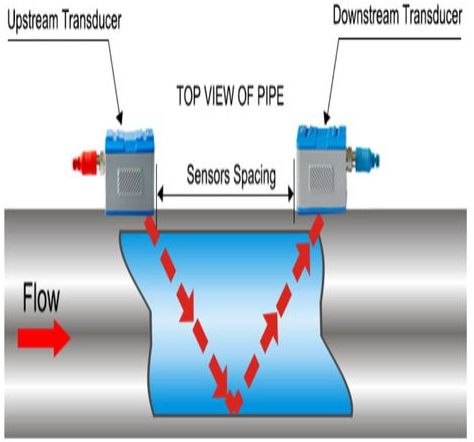

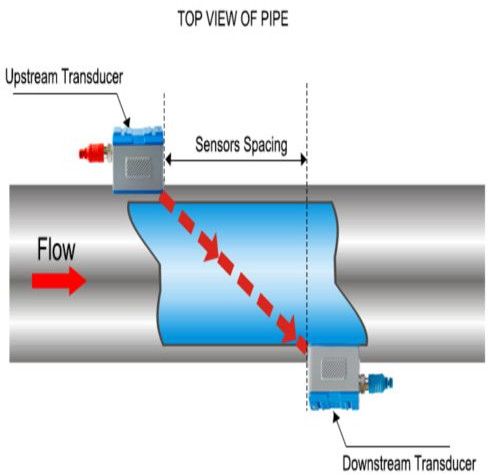

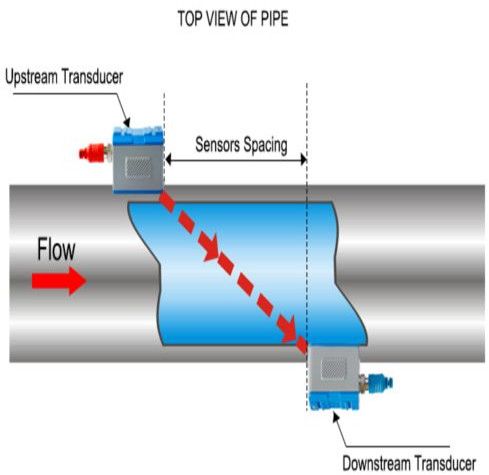

- CBRO make Ultrasonic flow meter works on the Transit Time or Time of Flight principle. The Flow meter unit utilizes two transducers that functions as both Ultrasonic transmitter and receiver. The transducers are either clamped on or inserted to the outside surface of the closed pipes. The transit time flow meter measures the time it takes for an ultrasonic signal transmitted from one transducer to cross the pipe and be received by second transducer. The flow is then measured by comparing the upstream and downstream time of Ultrasonic signal. With no flow through the pipe the transit time would be equal in both directions.

- For measuring the Flow of the medium, two ultrasonic pulses are sent through the medium, one in the flow direction and other in the opposite direction. The transit time of the two pulses are then measured. The transit time difference Δt between these two pulses gives the average flow velocity on the propagation path of the Ultrasonic signals. This can be used to obtain the average flow velocity on the cross section of the pipe, which is proportional to the volumetric flow.

Salient Features:

- Cost-effective and versatile

- High accuracy 1.0% reading

- Non-invasive, no moving parts, no pressure drop, no maintenance

- Easy and economical installation, no pipe cutting

- Wide measurement range 0.2 ~ 12m/s

- Wide pipe size range (DN 15 ~ 6000mm)

- Suitable for all commonly used pipe materials

- Bi-directional measurement. Totaliser display for net, positive and negative flow

- Ideal for both clean and opaque liquid flow measurement

Applications:

- Chemical, petrochemical and process industries

- Fertilizers industries

- Pharmaceutical industries

- Food and drug industries

- Sugar, beverage industries

- Paper and pulp industries

- Water and waste water management

- Dredging industries

- Mining industries.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Weight | < 0.5 Kg |

| Repeatability | 0.2% Of Span |

| Accuracy | ±1% Of Reading @ Rate > 0.5 M/sec. (Optional ±0.5% Of Reading) |

| Display | 4 lines, 16 characters, LCD with backlight, flow rate, velocity, totaliser |

| WeightS Sensor M Sensor L Sensor | < 0.3 kg < 0.5 kg < 1.0 kg |

| DimensionsS Sensor M Sensor L Sensor | 45x30x30 mm 60x45x45 mm 80x70x55 mm |

| Pipe sizeS Sensor M Sensor L Sensor | 15 – 80 mm 50 – 700 mm 400 – 4570 mm |

| Suited temp. – High | -40oC to 250oC |

| Suited temp. – Std. | -40oC to 120oC |

| Security | Keypad lockout, access code enabled |

| Dimensions | 204x90x30 mm |

| Protection class | IP 65, IP 67, IP 68 |

| Output | RS 232 |

| Totaliser | FWD, NET, REV, BATCH (Gallons, ft3, barrels, lbs, m3) |

| Units | User configurable English/Metric |

| Velocity | ±12 m/sec. Bidirectional |

| Power supply | 3 AAA NiMH built-in battery (12 hours of operation) & 100-240 V AC for the charger |

| Model | UFC250H |

| Make | CBRO |

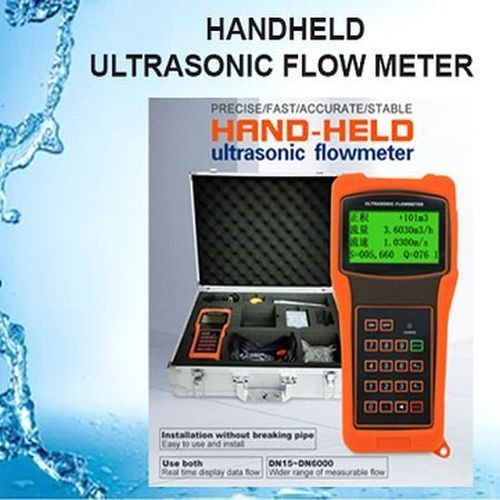

CBRO handheld ultrasonic flow meter realizes non-contact measurement of liquid flow. Install the sensor on the outer wall of the pipeline to complete the flow measurement. It has the characteristics of small size. Convenient carrying and accurate measurement. Handheld Ultrasonic Flow meter Principle Working: Time-transit measurement principle is adopted, the signal transmitted by one flow meter transducer passes through the pipe wall, the medium, the second transducer also transmits the signal received by the first transducer. The influence of the medium flow rate, there is a time difference, flow value Q can be obtained.

Application

Handheld Ultrasonic Flow Meter Applications

This flow meter is widely used in tap water, heating, water conservancy, metallurgy chemical,machinery, energy and other industries. It can be used for production monitoring, flow verification, temporary detection, flow inspection, water meter balance debugging,heating network balance debugging,energy-saving monitoring, and it is a necessary tool and meter for timely flow detection.

Installation

Handheld ultrasonic flow meter installation requirements

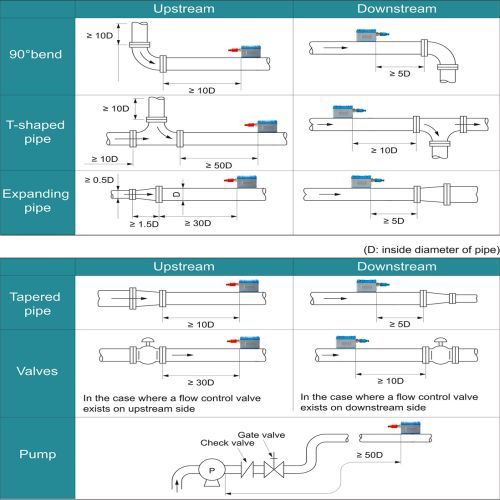

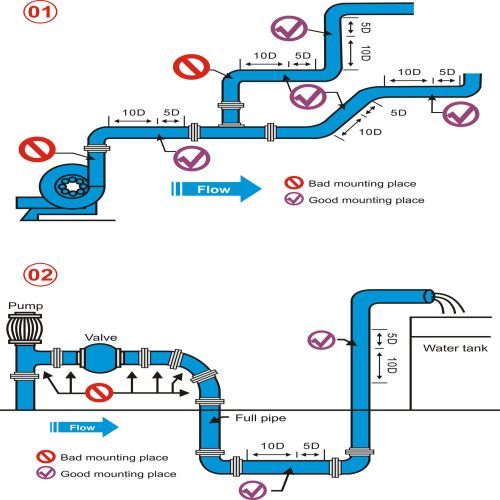

The state of the pipeline for measuring the flow will greatly affect the measurement accuracy, the detector installation location should be selected in a place that meets the following conditions:

1. It must be ensured that the straight pipe section where the probe is installed is: 10D on the upstream side(D is the pipe diameter), 5D or more on the downstream side, and there must be no factors that disturb the fluid(such as pumps,valves, throttles, etc.) in the 30D on the upstream side. And try to avoid the unevenness and welding position of the pipeline under test.

2. The pipeline is always full of liquid, and the fluid should not contain bubbles or other foreign objects. For horizontal pipelines, install the detector within ±45°of the horizontal centerline. Try to choose the horizontal centerline position.

3. When install the ultrasonic flow meter, need to input these parameters: pipe material,pipe wall thickness and pipe diameter. Fulid type, whether it contains impurities,bubbles, and whether the tube is full.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Ultrasonic Flow Meter |

| Country of Origin | India |

| Usage | Industrial, Measure Flow And Heat Of Clean And Uniform Liquids Without Large Concentration Suspended Particles Or Gases In Industrial Environment |

| Material | Stainless Steel |

| MODEL | CUF700 |

| Advantages | Accuracy Better Than ±1.0%, High Reliability, High Performance, Low Price, Bi-directional Flow Measurement, No Moving Parts, Maintenance-free |

| Installation | Select Pipe Section Filled With Fluid, Measuring Point 10 Times Diameter From Upstream, Straight Pipe Section Within 5 Times Diameter From Downstream, Consider Fouling Condition, Select Uniform And Dense Pipes |

| Make | CBRO |

| Size | DN15~DN6000 |

| Accuracy | Better than ±1.0% |

| Velocity range | 0~±10m/s |

| Liquid temperature | 0~160℃ |

| Liquid Type | Water, Sea Water, Waste Water, Alcohol, Beer, Various Kinds of Oil Etc Which Can Conduct Ultrasound |

| Pipe Material | Steel, Stainless Steel, Cast Iron, Copper, Pvc, Aluminum, Frp Etc, all Kinds of Dense Pipeline, Can |

| Output Signal | 1 Channel 4-20ma Output, Inpedence 0-1k ; 1 Channel Oct Pulse Output, Pulse Width 6-1000ms, (default |

| Communication | RS485 MODBUS RTU |

| Input Signal | 4-20ma Input Connect with Three Wire Pt100, Can Achieve Heat Measurement |

| Power supply | DC8-36V or AC85-264V |

| Protection | IP65 |

| Power Consumption | 1.5W |

| Brand | CBRO |

Flange ultraosnic flow meter is one kind of economy liquid flow meter which mainly measure various of pure liquid,such as:Clean water,Sea water,Dringking water,River water,Alcohol etc. And it is suitable for continuously measuring flow and heat of clean and uniform liquids without large concentration suspended particles or gases industrial environment.

Advantages :-

Accuracy better than ±1.0% High reliability, high performance, low price

Bi-directional flow measurement No moving parts, no wear, no pressure loss,Maintenance-free Measuring conductivity liquid and Non-conductivity liquid Display instantaneous flow,Total flow,Heat,Positive flow,Negative flow High precision machined pipe sections, the sensor is installed before leaving the factory to ensure high measurement accuracy

Installation :-

Integral Display Flange Ultrasonic Flow Meter Installation Requirement

Generally, the following principles should be followed:

To select a pipe section filled with fluid, such as a vertical part of the pipeline or a horizontal pipe section filled with fluid.

The measuring point should be 10 times the diameter from the upstream and the straight pipe section within 5 times the diameter from the downstream, and the distance from the valve outlet should be as far as possible.

Ensure the temperature at the measuring point is within the working range.

Fully consider the fouling condition of the inner wall of the pipe, and try to select a non-scaling pipe section for measurement. When it cannot be satisfied, fouling should be considered as a lining for better measurement accuracy.

Select pipe sections with uniform and dense pipes that are easy for ultrasonic transmission.

Please refer to the two examples on the right for the selection of measuring points.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Make | CBRO |

| Model | UBM250M |

| Accuracy | ±1% of reading at rates >0.2 mps |

| Repeatability | 0.2% |

| Principle | Transmit time |

| Velocity | ±32m/s |

| Pipe Size | DN15mm-DN6000mm |

| Display | Lcd with Backlight, Display Accumulated Flow/heat, Instantaneous Flow/heat, Velocity, Time Etc. |

| Signal Input | 3 Way 4-20ma Input Achieve to Heat Measurement By Connecting Pt100 Platinum Resistor |

| Pipe Material | Carbon Steel, Stainless Steel, Cast Iron, Cement Pipe, Copper, Pvc, Aluminum, Frp Etc. Liner is Allo |

| Straight Pipe Section | Upstram: 10d; Downsteam:5d; from the Pump:30d (d Means Outer Diameter) |

| Liquid Types | Water, Sea Water, Industrial Sewage, Acid & Alkali Liquid, Alcohol, Beer, all Kinds of Oils Which Ca |

| Liquid Temperature | Standard: -30℃ ~ 90℃ ,High-temperature:-30℃ ~ 160℃ |

| Liquid Turbidity | Less than 10000ppm, with a little bubble |

| Flow Direction | Bi-directional measuring, net flow/heat measuring |

| Power Supply | AC220V and DC24V |

| Power Consumption | Less than 1.5W |

| Communication | MODBUS RTU RS485 |

Modular type ultrasonic flow meter is one type ultrasonic flow meter with small size and competitive price. It’s working based on transmit-time working theory. One ultrasonic sensor send ultra-sound wave and another one sensor could receive this wave. The transmit time from send to receive have relationship with the velocity of flow speed. Then, converter could calculate the flow speed based the transmit time.

Advantages :-

Modular Type Ultrasonic Flow Meter Advantages and Disadvantages

1. Modular type ultrasonic flow meter is different with other type ultrasonic flow meters. It have much smaller size and could be installed into instrument box easily via DIN rail. It will save installation space.

2. It have multiple functions, such as LCD display, 4-20mA, pulse and RS485 output. No pressure loss, measurement is not affected by temperature and pressure changes. And the accuracy for it could reach ±1%.

3. Reliable empty full tube detection technology, Excellent low flow rate measurement performance, turndown ratio 100:1.

4. As a professional manufacturer, we could produce it with solar panel power system also. It’s very convenient for working site where don’ t have external power supply.

Application :-

Modular type ultrasonic flow meter used in tap water, heating, water conservancy, metallurgy, chemical, machinery, energy and other industries.

It can be used for production inspection, flow verification, temporary inspection, flow inspection, water meter horizontal debugging and energy saving monitoring.

It is a tool and meter for timely detection of flow.

Installation:-

Modular Type Ultrasonic Flow Meter Installation

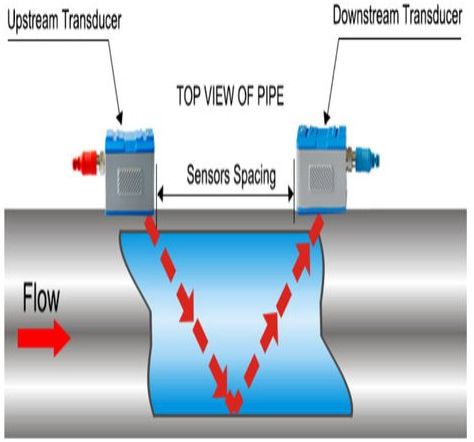

“V” method installation:

The “V” method installation is a relatively standard installation method, which is easy to use and accurate in measurement. When installing the two sensors, the center line of the two sensors can be aligned horizontally with the axis of the pipeline. It’s used on DN15mm and DN400mm.

“Z” method installation:

“Z” method of installation is the most commonly used method also. It is characterized by direct transmission of ultrasonic waves in the pipeline, no reflection (called single sound path), low signal attenuation loss. It’s used on DN100mm to DN6000mm.

Modular Type Ultrasonic Flow Meter Maintenance

1. Always observe whether the sensor power cable and transmission cable (or wire) of the instrument are damaged or aging. You need to protect the rubber sheath outside the cable.

2. For the clamp on type transducer ultrasonic flow meter, it is necessary to check whether the transducer is loose or not; whether the adhesive between it and the pipe is normal.

| Business Type | Manufacturer, Exporter, Supplier |

| Display | Backlit LCD |

| Material | Plastic |

| Driven Type | Electric |

| Make | CBRO |

| Model | OCFM2050 |

| Power Supply | Dc24V (±5%) 0.2A; AC220V (±20%) 0.1A ;Optinal DC12V |

| Flow Rate Range | 0.0000~99999L/S or m3/h |

| The maximum of Accumulative Flow | 9999999.9 m3/h |

| Accuracy of Change in Level | 1mm or 0.2% of full span (whichever is greater) |

| Resolution | 1mm |

| Analogue Output | 4-20mA, corresponding to instantaneous flow |

| Relays Output | Standard 2 relay outputs(Optional up to 6 relays) |

| Serial Communication | RS485, MODBUS-RTU standard protocol |

| Ambient Temperature | -40℃~70℃ |

| Measure Cycle | 1 second (selectable 2 seconds ) |

| Parameter Setting | 3 Induction Buttons / Remote Control |

| Cable gland | PG9 /PG11/ PG13.5 |

| Converter Housing Material | ABS |

| Converter Protection Class | IP67 |

| Sensor Level Range | 0~4.0m ;other level range also available |

| Blind zone | 0.20m |

| Temperature Compensation | Integral in probe |

| Pressure Rating | 0.2MPa |

| Beam Angle | 8° (3db) |

| Cable Length | 10m standard (can be extended to 1000m) |

| Sensor Material | ABS, PVC or PTFE (optional) |

| Sensor Protection Class | IP68 |

| Connection | Screw (G2) or flange (DN65/DN80/etc.) |

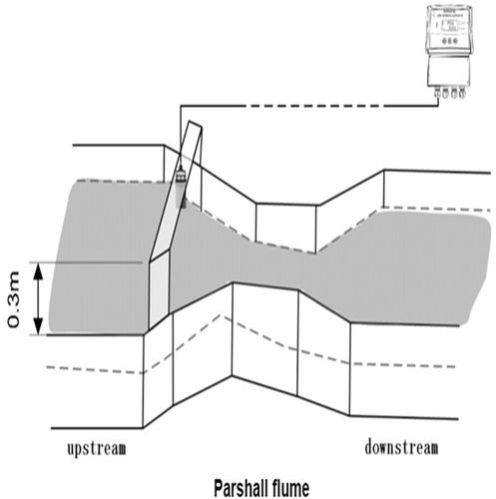

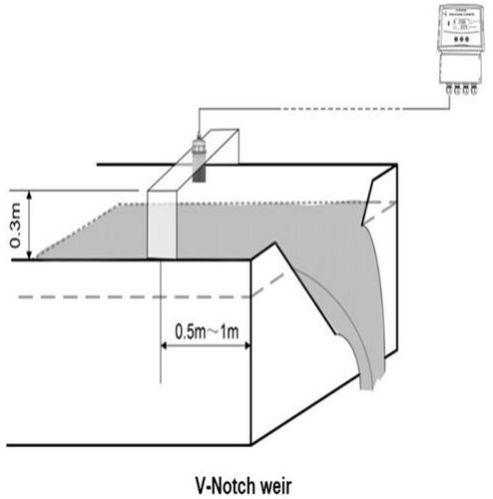

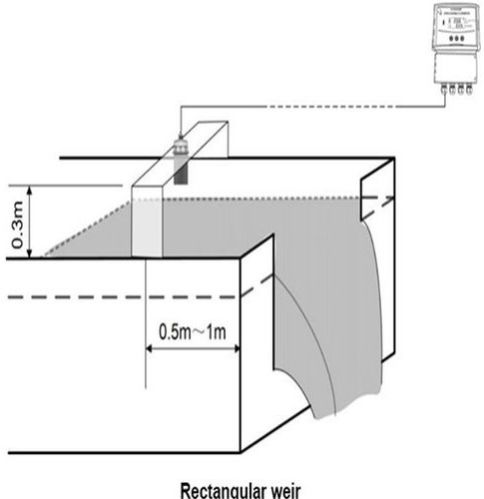

Open Channel Flow Meter is an economical solution for open channel measuring, which measures level, flow rate and total volume of water flowing through weirs and flumes. The meter includes a non-contact ultrasonic level sensor to detect the water level and then calculates the flow rate and volume using the Manning equation and characteristics of the channel.

Advantages

Open Channel Flow Meter Advantages and Disadvantages

Economical and reliable. The accuracy of change in level is 1 mm. Suitable for a variety of weirs and flumes, Parshall flumes (ISO), V-Notch weirs, Rectangular weirs(With or Without End Contractions) and custom Formula type weir; Displays flow rate in L/S , M3/h or M3/min; Clear display with Graphical LCD(with backlight) ; The cable length between probe and host up to 1000m; The probe with leak-proof structure and IP68 protect grade; Chemically resistant probe materials for maximum application flexibility; Provided 4-20mA output and RS485 serial communication (MODBUS-RTU) output; Provided programmable 6 relays at most for alarms; Three button for programming easy configuration and operation(opt.)

Installation

Open channel flow meter Hints for probe mounting

1. The probe can be supplied as standard or with a screw nut or with an ordered flange.

2. For applications requiring chemical compatibility the probe is available fully enclosed in PTFE.

3. The use of metallic fittings or flanges is not recommended.

4. For exposed or sunny locations a protective hood is recommended.

5. Make sure that the probe is mounted perpendicular to the monitored surface and ideally, at least 0.25 meters above it, because the probe cannot get response in the blind zone.

6. The probe has a 10 inclusive conical beam angel at 3 db and must be mounted with a clear unobstructed sight of the liquid to be measured. But smooth vertical sidewalls weir tank will not cause false signals.

7. The probe must be mounted upstream of the flume or weir.

8. Do not over-tighten the bolts on flange.

9. The stilling well can be used when there is volatility in the water or needs to improve the accuracy of level measurement. The still well connect with the bottom of the weir or flume, and the probe measures the level in the well.

10. When install to the cold area, should choose the lengthen sensor and make the sensor extend into the container, shun frost and icing.

11. For Parshall flume, the probe should be installed in a position the 2/3 contraction away from the throat.

12. For V-Notch weir and rectangular weir, the probe should be installed on the upstream side, the maximum water depths over the weir and 3~4 times away from the weir plate.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Automatic Grade | Automatic |

| Application | Industrial |

CBRO UFM250H portable clamp-on Ultrasonic Flowmeter is one of the most powerful Flowmeters available for liquid measurement. The utilisation of our ultrasonic signal processing, transit-time measurement and signal quality tracking technologies allow the Flowmeter to measure liquid flow rate from outside of a pipe reliably and accurately.

The Flowmeter is carefully designed, so that it is very compact and easy to use. A user can use hand to hold as well as to operate the Flowmeter main unit. The user-interface is self-explanatory and very easy to follow. Besides, the unique clamp-on fixture design makes the installation very simple and no special skills or tools required. Due to the non-intrusive nature of the clamp-on technique, there is no pressure drop, no moving parts, no leaks and no contamination.

Salient Features:

- Cost effective and versatile

- High accuracy 1.0% reading

- Non invasive, no moving parts, no pressure drop, no maintenance

- Easy and economical installation, no pipe cutting

- Wide measurement range 0 ~ 12m/s

- Wide pipe size range (DN 15 ~ 4570mm)

- Suitable for all commonly used pipe materials

- Bi-directional measurement. Totaliser display for net, positive and negative flow

- Ideal for both clean and opaque liquid flow measurement

Applications:

- Chemical, petrochemical and process Industries

- Fertilizers industries

- Pharmaceutical industries

- Food and drug industries

- Sugar, beverage industries

- Paper and pulp industries

- Water and waste water management

- Dredging industries

- Mining industries

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CBRO |

CBRO UFM250I inline type Flanged Battery Operated Ultrasonic Flowmeter provides abundant capabilities for accurate liquid flow measurement. It is widely used in remote location applications where Field Electric supply is not available.

Salient Features:

- Based on Transit Time technology

- Flow tube sizes 15 mm to 600 mm

- Battery powered with 5 years life

- Integral or remote transmitter

- Field interchangeable electronics

- GSM or GPRS AMR functionality

- Unique IP 68 rated transmitter housing

- High long-term stability and reliability

Applications:

- Process industries

- Water and waste water management

- Dredging industries

- Mining industries

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CBRO |

| Condition | New |

| Country of Origin | India |

| MODEL | UWM-Smart1060 |

| Type | Ultrasonic Water Meter |

| Technology | Ultrasonic With AMR (Automatic Meter Reading) |

| Display | Full Information LCD Display |

| Communication | Multi Communication Support |

| Alarm Indication | 5 Different Alarms |

| Installation | Easy Due To Compact Size |

| Battery Life | Long Battery Life |

| Application | Industrial R.O.,Residential Water Metering,Water Supply Schemes,Smart Water Billing,Industrial And Residential Water Metering |

Accumax offers smart flow meter devices, which provide accurate, cost effective and contemporary flow measurement for household and industries application. It is an advanced and highly accurate ultrasonic water meter with AMR (Automatic meter reading) technology. It can be used for industrial application as well as for residentials application. The ultrasonic AMR water flow meter measurement is based on the transit time method also It has full information LCD display, which is easy to read the data and see the alarms. Ultrasonic AMR meter has wide applications as it’s based on LORA technology and automatic reading meter (AMR)

Features:

- Because of LORA module, Long range transmission is possible

- In-built data logger in order to see history record

- Transit time ultrasonic technology in order to provide accuracy and ultra-reliable metering

- Multi communication support

- Dedicated daily information details availability

- Different 5 Alarm indication

- Easy to install due to compact size

- Long battery life

Application:-

- Industrial R.O.

- Residential water metering

- Water supply schemes

- Smart water billing

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CBRO |

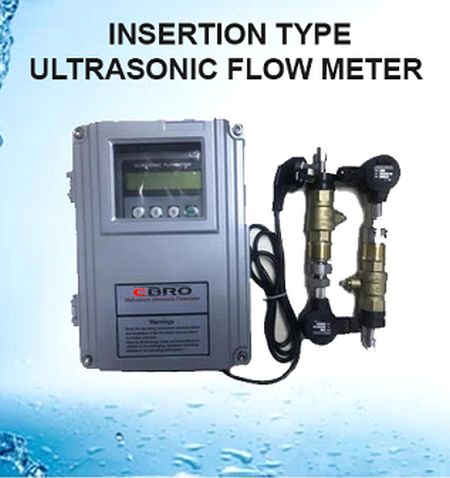

Salient Features:

- Cost-effective and versatile

- High accuracy 1.0% reading

- Non invasive, no moving parts, no pressure drop, no maintenance

- Easy and economical installation, no pipe cutting

- Wide measurement range 0.2 ~ 12m/s

- Wide pipe size range (DN 15 ~ 4570mm)

- Suitable for all commonly used pipe materials

- Bidirectional measurement. Totaliser display for net, positive and negative flow

- Ideal for both clean and opaque liquid flow measurement

Applications:

- Chemical, petrochemical and process industries

- Fertilizer industries

- Pharmaceutical industries

- Food and drug industries

- Sugar, beverage industries

- Paper and pulp industries

- Water and waste water management

- Dredging industries

- Mining industries