Vortex Flow Meters

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Field Display Vortex Flow Meter, Remote Type Vortex Flow Meter and Vortex Flow Meter from Thane.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

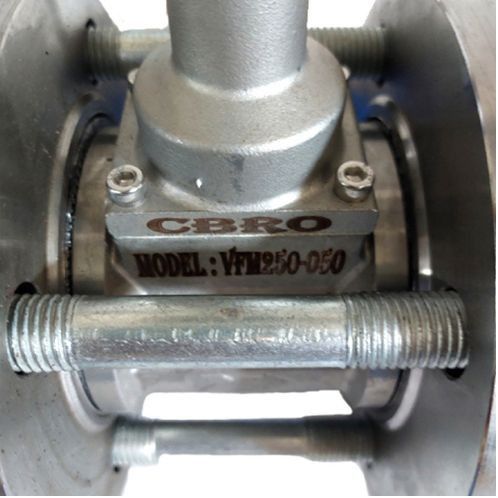

| Make | CBRO |

| Model | VFM250 |

| Measured Medium | Liquid, Gas, Air, Steam , Vapor |

| Medium Temp | -40℃~+200℃; -40℃~+280℃; 40℃~+350℃ |

| Nominal Pressure | 1.6mpa; 2.5mpa; 4.0mpa(other Pressure Can Be Custom, Need Consult Supplier) |

| Accuracy | 0.5% for Liquids 1% for Gas & Steam , 1.5%(insertion Type) |

| Measuring Range Ratio | 1:10(standard Air Condition as Reference) 1:15(liquid) |

| Flow Range | Liquid:0.4-7.0m/s; Gas:4.0-60.0m/s; Steam:5.0-70.0m/s |

| Max. Working Pressure | 6 Mpa |

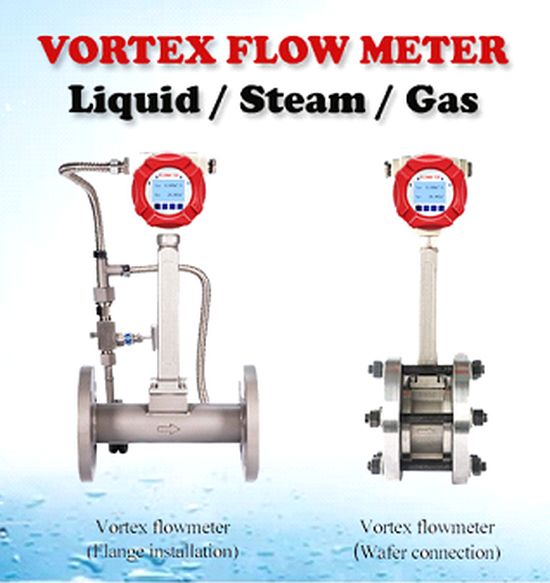

| End Connections | Thread (M/F)/ Flange / Sandwich |

| Material | SS304(Standard), SS316(Optional) |

| Display | 3.3 V10AH lithium batteries can be used more than 5 years in a row |

| Output | 3 Wire Pulse / 2 Wire 4-20mA / RS485 Modbus / HART |

| Iep Atex | II 1G Ex ia IIC T5 Ga |

| Power Supply | 12-24V/DC or 3.6V battery powered |

Flange vortex flow meter is used in numerous branches of industry to measure the volume flow of liquids, gases and steam. Applications in the chemicals and petrochemicals industries, for example, in power generation and heat-supply systems involve widely differing fluids: saturated steam, superheated steam, compressed air, nitrogen, liquefied gases, flue gases, carbon dioxide, fully demineralized water, solvents, heat-transfer oils, boiler feedwater, condensate, etc.

Advantages :-

Vortex flow meter advantages and disadvantages

Vortex flow meter body is robust and universally applicable for liquids, gases and steam,optimized for steam applications. CBRO Vortex flow meter adopt Japan OVAL technology and design. To protect the sensor, CBRO vortex flow meter choose embedded sensor, with 4 piezo-electric crystal encapsulated inside the sensor, which is our own patent. There is no moving parts, no abrasion, non-wearing parts inside the vortex flow meter sensor, fully welded SS304 body (SS316 selectable). With patented sensor and flow sensor body, CBRO vortex flow meter could eliminate drift & vibration influence from great aspect in the working site while compare with other flow meters.

Application :-

Vortex flow meter application

Vortex flow meter is professional in measuring non-conductive liquids, gases, saturated and superheated steam, especially for steam measurement trade settlement.

Except work as flow meter, vortex flow meter can also work as heat meter to measure the Gross/net heat of steam and hot water.

Vortex flow meter usually monitor the compressor output and evaluation of Free Air Delivery (FAD)

There has lots of Industrial gases, such as natural gas, nitrogen gas, liquefied gases, flue gases, carbon dioxide etc, all could use vortex flow meter.

In many factories, compressed air monitoring is very important, vortex flow meter also could use for process control. Besides the different gases measurement, vortex flow meter could also used for light oil or any purified water,such as thermal oils, Desalinated water, demineralized water, RO water, boiler feed water, condensate water etc.

In the Chemicals and petrochemicals industries, there also has lots of gases or liquid could use vortex flow meter for monitoring.

Installation :-

1. The installation of vortex flow meter has higher requirements, to guarantee the better accuracy and working properly. Vortex flow meter installation should keep away from the electric motors, big frequency converter, power cable, transformers, etc.

Do not install in the position where there has bends, valves, fittings, pumps etc, which could cause flow disturbances and influence the measurement.

The front straight pipe line and after straight pipe line should follow below suggestion.

2. Vortex Flow Meter Daily Maintenance

Regular cleaning: The probe is an important structure of the vortex flowmeter. If the detection hole of the probe is blocked, or is entangled or wrapped by other objects, it will affect the normal measurement, resulting in inaccurate results;

Moisture-proof treatment: most of the probes have not undergone moisture-proof treatment. If the use environment is relatively humid or is not dried after cleaning, the performance of the vortex flow meter will be affected to a certain extent, resulting in poor operation;

Minimize external interference: strictly check the grounding and shielding conditions of the flow meter to ensure the accuracy of the flow meter measurement;

Avoid vibration: There are some parts inside the vortex flowmeter. If strong vibration occurs, it will cause internal deformation or fracture. At the same time, avoid the inflow of corrosive liquid.

| Business Type | Manufacturer, Exporter, Supplier |

| MAKE | CBRO |

| Model | VFM250-R |

| Measured Medium | Liquid, Gas, Air, Steam , Vapor |

| Medium Temp | -40℃~+200℃; -40℃~+280℃; 40℃~+350℃ |

| Nominal Pressure | 1.6MPa; 2.5MPa; 4.0MPa(Other Pressure Can Be Custom, Need Consult Supplier) |

| Measuring range ratio | 1:10(Standard air condition as reference) 1:15(Liquid) |

| Flow Range | Liquid:0.4-7.0m/s; Gas:4.0-60.0m/s; Steam:5.0-70.0m/s |

| Max. Working Pressure | 6 Mpa |

| End Connections | Thread (M/F)/ Flange / Sandwich |

| Material | SS304(Standard), SS316(Optional) |

| Display | 3.3 V10AH lithium batteries can be used more than 5 years in a row |

| Output | 3 Wire Pulse / 2 Wire 4-20mA / RS485 Modbus / HART |

| IEP ATEX | II 1G Ex ia IIC T5 Ga |

| Power Supply | 12-24V/DC or 3.6V battery powered |

Remote Wallmounted Vortex Flow Meter is used in numerous branches of industry to measure the volume flow of liquids, gases and steam. Applications in the chemicals and petrochemicals industries, for example, in power generation and heat-supply systems involve widely differing fluids: saturated steam, superheated steam, compressed air, nitrogen, liquefied gases, flue gases, carbon dioxide, fully demineralized water, solvents, heat-transfer oils, boiler feedwater, condensate, etc.

Advantages :-

Vortex flow meter advantages and disadvantages

Vortex flow meter body is robust and universally applicable for liquids, gases and steam,optimized for steam applications. In gas measurement, vortex flow meter could achieve high accuracy ±0.75%~±1.0% of reading ( gas ±1.0%, liquid ±0.75%); which could use in custody transfer , while the metal tube rotameter or orifice plate usually use for process control. With a variety of signals outputs and selection, such as 4-20mA, pulse with HART or pulse with RS485 are selectable.

In the electronic device of measuring flow, vortex flow meter is the only one could resist wide temperature range up to highest temperature 350℃, digital flow meter highest process temperature.

Application :-

Vortex flow meter applications

Vortex flow meter is professional in measuring non-conductive liquids, gases, saturated and superheated steam, especially for steam measurement trade settlement.

Except work as flow meter, vortex flow meter can also work as heat meter to measure the Gross/net heat of steam and hot water.

Vortex flow meter usually monitor the compressor output and evaluation of Free Air Delivery (FAD)

There has lots of Industrial gases, such as natural gas, nitrogen gas, liquefied gases, flue gases, carbon dioxide etc, all could use vortex flow meter.

In many factories, compressed air monitoring is very important, vortex flow meter also could use for process control.

Besides the different gases measurement, vortex flow meter could also used for light oil or any purified water,such as thermal oils, Desalinated water, demineralized water, RO water, boiler feed water, condensate water etc.

In the Chemicals and petrochemicals industries, there also has lots of gases or liquid could use vortex flow meter for monitoring.

Installation :-

Vortex Flow Meter Installation Requirements

The installation of vortex flow meter has higher requirements, to guarantee the better accuracy and working properly.

Vortex flow meter installation should keep away from the electric motors, big frequency converter, power cable, transformers, etc.

Do not install in the position where there has bends, valves, fittings, pumps etc, which could cause flow disturbances and influence the measurement.

The front straight pipe line and after straight pipe line should follow below suggestion.

| Business Type | Manufacturer, Exporter, Supplier |

| Make | CBRO |

| Model | VFM250 |

| VFM250 | Liquid / Gas / Steam |

| Diameter | 10,15,20,25,32,40,50,65,80,100,150,250,300,(300~1000) |

| Temperature | Piezoelectric:-40~60ºC Capacitive:-40~300ºC |

| Material | Stainless steel material |

| Vibration Acceleration | Piezoelectric:0.2g Capacitive:1.0~2.0g |

| Accuracy | 1.0%FS;1.5%FS; Insert type:2.5%FS |

| Flow ratio | 1:6~1:30 |

| Power supply | Flow Sensor:12VDC/24VDC / Battery: 3.6V |

| Output | Pulse ,4~20mA Output ; Battery supply can not provide any output |

| Explosion | ExdIIia CT2~T5 or ExdII CT2~CT5 |

| Protection | IP65 or IP68 |

CBRO vortex flowmeter is used for measuring the flow velocity of gases or liquids in pipelines flowing full. The measuring principle is based on the development of a Karman vortex shedding street in the wake of a body built into the pipeline. The periodic shedding of eddies occurs first from one side and then from the other side of a bluff body (vortex-shedding body) installed perpendicular to the pipe axis. Vortex shedding generates a so called "Karman vortex street" with alternating pressure conditions whose frequency is proportional to the flow velocity.

Features:

- Lattice LCD display

- Easy operation

- Configure with temperature/pressure senor. For temperature sensors, Pt100 or Pt1000; For pressure sensor, gauge pressure sensor or absolute pressure sensor

- Multiple Outputs can be optional: Two-Wire 4-20mA, Three-Wire pulse and Three-Wire equivalent output

- Excellent nonlinearity correction function, greatly improve the appearance of linearity

- Spectral analysis, improve the ability of anti-interference and vibration resistance

- A variety of measuring medium: vapor, liquid, gas and natural gas, etc.

- Low power consumption, a dry cell can maintain at least 3 years

- Automatic switching ability of the working modes: Battery supply, Two-Wire and Three-Wire

- Self-checking function: the rich self-checking information make easy maintenance and debugging

- Independent password setup, the parameters setup, total flow reset and calibration can be set with different- level passwords, it is convenient for management

- Three-Wire system supports RS485 communication The display unit can be selected and user-defined