| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Make | CBRO |

| Model | DIGIMAG250 Series |

| Click to view more | |

Product Details

Electromagnetic flow meter is one of the most popular flow meters. Flange type electromagnetic flow meter has been used for more than 50 years worldwide. It is widely used for all conductive liquids in every industry, such as water, acid, alkali, milk, slurry etc. Since founded in 2005, CBRO has sold more than 600 thousand electromagnetic flow meters to provide the solutions for clients in different work conditions.

Advantages :-

Electromagnetic Flow Meter Advantages and Disadvantages

The main advantages of using electromagnetic flow meter is that it is with no moving parts, no pressure loss and require very less maintenance.

Flange type magnetic flow meter can be made large size range from DN3-DN3000mm and with bi-directional flow measurement. CBRO mag flow meters are with built-in self-diagnosis function and support data record / bluetooth function and various kinds of output signals. Electromagnetic flow meter will be affected if there’s strong magnetic filed in the surrounding environment.

Application :-

Flange Electromagnetic Flow Meter Installation Requirement

Electromagnetic flow meter is widely used in water treatment, food industry, pharmaceutical, petrochemical, paper mill, chemical monitoring etc.

In the metallurgical industry, it is often used to control the flow of cooling water for continuous steel casting, continuous steel rolling, and steel-making electric furnaces;

In the field of water supply and drainage in public utilities, electromagnetic flow meters are often used for the transfer measurement of finished product water and raw water in water plants;

In the pulp process of the paper industry, electromagnetic flow meters are involved in the measurement of the flow of grinding pulp, water, acid, and alkali;

In the coal industry, measuring coal washing and pipeline hydraulic conveying coal slurry.

For food and beverage industries, it is used for beer and beverage filling measurement.

For chemical and petrochemical industries, it is used to measure corrosive liquids, such as acids and alkalis etc

Installation :-

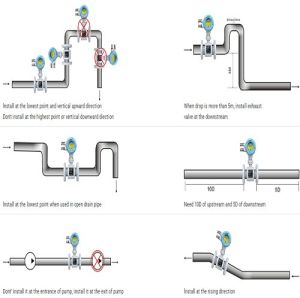

Flange Electromagnetic Flow Meter Installation Requirement

In order to obtain a stable and accurate flow measurement, it is very important that the flow meter is installed correctly in the pipe system.

Do not install the meter near equipment that produces electrical interference such as electric motors, transformers, variable frequency, power cables etc.

Avoid locations with pipe vibrations for example pumps.

Do not install the meter close to pipeline valves, fittings or impediments which can cause flow disturbances.

Place the meter where there is enough access for installation and maintenance tasks.

Raise your Query

Hi! Simply click below and type your query.

Our experts will reply you very soon.