Electromagnetic Flow Meters

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Battery Powered Electromagnetic Flow Meter, DIGIMAG250 Full Bore Electromagnetic Flow Meter, Electromagnetic Flow Meter, Electromagnetic Flow Meter With Telemetry System, Flange Electromagnetic Flow Meter, Insertion Electromagnetic Flow Meter, Partially Filled Pipe Electromagnetic Flow Meter, POWERMAG2500 Full Bore Electromagnetic Flow Meter, Tri-clamp Electromagnetic Flow Meter and Wafer Electromagnetic Flow Meter from Thane.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Make | CBRO |

| Model | POWERMAG2500 |

| SIZE | DN3-DN3000MM |

| Nominal Pressure | 0.6-1.6Mpa(2.5Mpa/4.0Mpa/6.4Mpa...Max 42Mpa) |

| Accuracy | +/-0.5%(Standard) +/-0.3% or +/-0.2%(Optional) |

| Liner | PTFE, Neoprene, Hard Rubber, EPDM, FEP, Polyurethane, PFA |

| Electrode | SUS316L, Hastelloy B, Hastelloy C Titanium, Tantalum, Platinium-iridium |

| Structure Type | Integral type, remote type, submersible type, ex-proof type |

| Ambient Temperature | -20~+60deg C |

| Ambient Humidity | 5-100%RH(relative humidity) |

| Measuring Range | Max 15m/s |

| Conductivity | >5us/cm |

| Protection Class | IP65(Standard); IP68(Optional for remote type) |

| Process Connection | Flange (Standard), Wafer, Thread, Tri-clamp etc (Optional) |

| Output Signal | 4-20mA/Pulse |

| Communication | RS485(Standard), HART(Optional),GPRS/GSM (Optional) |

| Power Supply | AC220V (can be used for AC85-250V) DC24V (can be used for DC20-36V) DC12V (optional), Battery Powere |

| Power Consumption | <20W |

Battery-powered magnetic flow meter can be used in remote area where don’t have power grid . It is widely used for all conductive liquids in every industry, such as water, acid, alkali, milk, slurry etc. Since founded in 2005, CBRO has been focused in magnetic flow meter manufacturing for more than 15 years. More than 600 thousand mag meters had been provided to clients all over the world for different work conditions.

Advantages :-

Battery Powered Electromagnetic Flow Meter Advantages and Disadvantages

has a long life span, standard battery can work for 3-6 years, determined by the excitation current

2.Dual power supply: it’s equipped with external power supply interface, which

can be powered by external 12-24vdc power supply, enabling users to have a variety of power options;

3. Multiple network interfaces: W803 has GPRS, RS485, HART and other network communication for users;

4.Multiple work mode: W803E has ‘Flow Only’ mode, ‘Flow + Pressure’ mode, ‘Flow + Temperature’ mode for users.

Application :-

Electromagnetic flow meter is widely used in water treatment, food industry, pharmaceutical, petrochemical, paper mill, chemical monitoring etc.

In the metallurgical industry, it is often used to control the flow of cooling water for continuous steel casting, continuous steel rolling, and steel-making electric furnaces; In the field of water supply and drainage in public utilities, electromagnetic flow meters are often used for the transfer measurement of finished product water and raw water in water plants; In the pulp process of the paper industry, electromagnetic flow meters are involved in the measurement of the flow of grinding pulp, water, acid, and alkali; In the coal industry, measuring coal washing and pipeline hydraulic conveying coal slurry.

For food and beverage industries, it is used for beer and beverage filling measurement.

For chemical and petrochemical industries, it is used to measure corrosive liquids, such as acids and alkalis etc.

Installation :-

Battery Powered Electromagnetic Flow Meter Installation Requirement

In order to obtain a stable and accurate flow measurement, it is very important that the flow meter is installed correctly in the pipe system.

Do not install the meter near equipment that produces electrical interference such as electric motors, transformers, variable frequency, power cables etc.

Avoid locations with pipe vibrations for example pumps.

Do not install the meter close to pipeline valves, fittings or impediments which can cause flow disturbances.

Place the meter where there is enough access for installation and maintenance tasks.

| Business Type | Manufacturer, Exporter, Supplier |

| Make | CBRO |

| Model | DIGIMAG250 |

| Nominal dia (mm) | 10 to 3000 |

| Working pressure (kg/cm2) | 10, 16, 25, 40 |

| Working temperature | Integral PTFE – 120oC Remote PTFE – 180oC Others – 70oC |

| Electrode material | SS 316L Std.* |

| Sensor lining | Std. Rubber* |

| Display version | Integral/Remote |

| Measuring tube material | SS 304 Std.* |

| Sensor housing material | Std. CS* |

| End connection | Flange/Wafer/Tri-clamp/SMS |

| Flange standard | ANSI 150* |

| Measuring range | 0.2 to 12 m/sec. Bidirectional |

| Accuracy % of measured value | ±O.5% (±O.2% consult factory) |

| Repeatability | ±0.2% of Span |

| Display | 2 line LCD |

| Display units | All standard engineering units in m3, litre, gallon, ft3, imperial gallon |

| Output | Std. 4 – 20 mA* |

| Power supply | 12 – 60 V DC or 80 – 300 V AC/DC Solar powered |

| Protection class for sensor | Std. IP 65 Option IP 67/IP 68 for flow tube in remote type |

| Protection class for transmitter | IP 67 |

| Cable length for remote | Std. 10 m* |

| Installation | Inline flanged type |

| Note | For options please refer to order code from catalogue |

Electromagnetic flow measurement has been in use around the world for 50 years and more, as witnessed by the popularity of these meters that continues unabated in virtually all sectors of industry. Electromagnetic Flowmeters can be used to measure all electrically conductive liquids (> 5 µS/cm) with or without solids, e.g. water, wastewater, sludge, slurries, pastes, acids, alkalis, juices, fruit pulp, etc.

CBRO DIGIMAG250 Full Bore Electromagnetic Flowmeter is suitable for the most demanding applications. It is based on Faraday’s law of Electromagnetic Induction. The meter features flanged construction and is available with choice of liner and electrode material. All meters consist of a sensor and a converter that may be mounted either integral to the sensor or remotely with a field mount kit. CBRO Flowmeters are calibrated at our own Water Flow Calibration Facility. It uses the primary method of measuring the water flow by gravimetric principle. The facility is designed for calibration of flowmeters under controlled and stable flow conditions.

Salient Features:

- Based on Faraday’s law of electromagnetic induction

- Flow tube sizes 10 mm to 3000 mm and above

- Coil assembly in hermetically sealed welded construction

- Integral or remote transmitter

- Field interchangeable electronics

- High linearity due to characteristic magnetic field

- Absolute zero stability and noise elimination due pulsed DC excitation

- High long-term stability and reliability

Applications:

- Chemical, petrochemical and process industries

- Fertilizers industries

- Pharmaceutical industries

- Food and drug industries

- Sugar, beverage industries

- Paper and pulp industries

- Water and waste water management

- Dredging industries

- Mining industries

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Make | CBRO |

| Model | DIGIMAG250 Series |

| Flow direction | Positive/negative/net flow |

| Range Ratio | R160/250/400(Optional) |

| Accuracy Class | 1 class/2 class(Optional) |

| Pressure Loss | ∆P40 |

| Temperature | T50 |

| Pressure | 1.6mpa(special Pressure Can Be Customized) |

| Conductivity | ≥20μS/cm |

| Initial flow velocity | 5mm/s |

| Output | 4-20mA, Pulse |

| Flow profile sensitivity class | U5,D3 |

| Connection Type | Flanged,GB/T9119-2010 |

| Protection | IP68 |

| Ambient temperature | -10℃~+75℃ |

| Relative humidity | 5%~95% |

| Installation Type | Horizontal and Vertical |

| Electrode Material | 316l |

| Material | Carbon Steel/ Stainless Steel (optional) |

Electromagnetic water meter is a kind of instrument for measuring the volume flow of conductive liquid based on Faraday’s principle of electromagnetic induction. It has the characteristics of wide range, low initial flow, low pressure loss, real-time measurement, cumulative measurement, bi-direction measurement, etc. It mainly uses DMA zoning, online monitoring, water loss analysis and statistical settlement of water supply mains.

Advantages :-

1 No blocking parts inside of measuring tube, low pressure loss and low requirements for straight pipeline.

2 Variable diameter design, improve measurement accuracy and sensitivity, reduce excitation power consumption.

3 Select suitable electrodes and liner, with good corrosion resistance and wear resistance.

4 Full electronic design, strong anti-interference ability, reliable measurement, high accuracy, wide flow range.

Application :-

Electromagnetic water meter is a metering instrument specially designed for the actual requirements of water supply enterprises, specially designed for water industry, which can optimize water supply and ensure accurate water trade measurement and settlement. Practice has proved that electromagnetic water meter is the ideal choice to solve the measurement contradiction of large water users. In addition, electromagnetic water meters are widely used in chemical industry, environmental protection, metallurgy, medicine, paper making, water supply and drainage and other industrial technology and management departments.

Installation :-

Installation environment selection

1. Stay away from devices with strong electromagnetic fields. Such as large motor, large transformer, large frequency conversion equipment.

2. The installation site should not have strong vibration, and the ambient temperature does not change much.

3. Convenient for installation and maintenance.

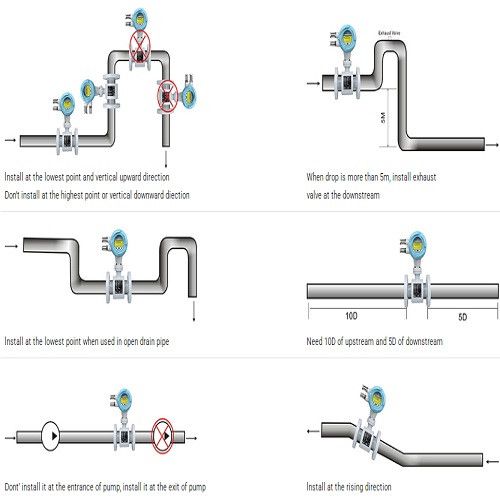

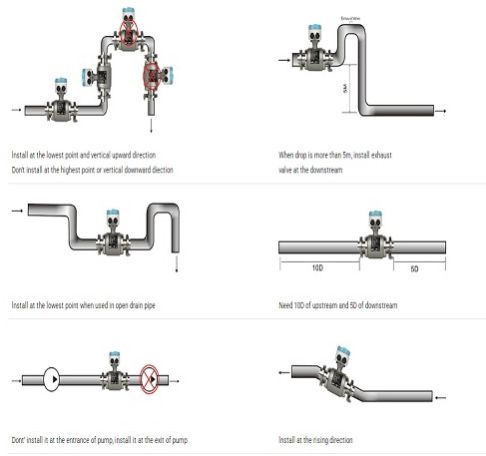

Selection of installation location

1. The flow direction mark on the sensor must be consistent with the flow direction of the measured medium in the pipeline.

2. The installation position must ensure that the measuring tube is always filled with the measured medium.

3. Select the place where the fluid flow pulse is small, that is, it should be far away from the water pump and local resistance parts (valves, elbows, etc.)

4. When measuring the two-phase fluid, choose the place which is not easy to cause phase separation.

5. Avoid installation in the area with negative pressure in the tube.

6. When the measured medium easily causes the electrode and the inner wall of the measuring tube to adhere to and scale, it is recommended that the flow rate in the measuring tube be no less than 2m/s. At this time, a tapered tube slightly smaller than the process tube can be used. In order to clean the electrode and measuring tube without interrupting the flow in the process tube, the sensor can be installed in parallel with a cleaning port.

| Business Type | Manufacturer, Exporter, Supplier |

| Line sizes | 15 mm to 1000 mm |

| Brand | CBRO |

| Accuracy | ±0.5 % +-(1mm/sec) of Actual Flow Rate between 100 % to 10 % of calibrated range |

| Liner Material | HR, PTFE, PFA, Neoprene, Rubber , Hard Rubber |

| Electrode MOC | SS316, Hastalloy C, TAN, TI |

| Flange Standard | ANSI / DIN / BS 10 E / BS 10 F / IS |

| Flange / Coil Housing MOC | MS / CS / SS 316 / SS 304 |

| Operating Pressure | Up to DN 80 – PN 40, From DN 100 to DN 200 – PN 16, From DN 250 to DN 350 – PN 10 |

| Operating Temperature | HR : 0 – 90 ºC / PTFE : 0 – 150 ºC / PFA : 0 – 200 ºC / Neoprene : 0 – 90 ºC |

| Transmitter Mounting | Remote / Integral |

| Types of Transmitters | Integral / Remote Wall Mounted |

| Display Type | 16 characters x 2 rows LCD Display for instantaneous Flow rate, Totaliser, Engg. units |

| Velocity Range | 2.5 m/s to 10 m/s |

| Communication | RS485(default) / RS 232(optional) / GPRS / GSM / WIFI |

CBRO Make Digital Flow Meter with Telemetry System as per the latest Central Groundwater Authority(CGWA) Guidelines. Also, this Digital Flow Meter with a Telemetry system is easy to install and user-friendly. It provides an IoT platform for water meters which is suitable for data acquisition from any remote location. Also, its Cloud platform having Real-Time Dashboard that allows viewing all analytical parameters as per CGWA guidelines.

Alerts or Notifications during parameter exceedance will be received through Email and SMS.

Features:

- Digital display for instantaneous flow reading.

- Followed by CGWA, CGWB, and CSWA/B guidelines.

- Remotely accessible because it provides an IOT platform for the water flow meters.

- Tampering Alert on Dashboard.

- Power failure Indication.

- Backup of data as per request.

- No Pressure drop in flow.

Two variants are available:

- Electromagnetic Flowmeter with Inbuilt Telemetry System

- Electromagnetic Flowmeter with External Telemetry System

Applications:

- Steel & Aluminum

- ETPs & STPs

- Sugar & Distilleries

- Paper & Pulp

- Food & Drug

- Petrochemical

- Fertilizer and Chemical

- Pharmaceutical

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Make | CBRO |

| Model | DIGIMAG250 Series |

| Size | DN3-DN3000mm |

| Nominal Pressure | 0.6-1.6Mpa(2.5Mpa/4.0Mpa/6.4Mpa...Max 42Mpa) |

| Accuracy | +/-0.5%(Standard) +/-0.3% or +/-0.2%(Optional) |

| Liner | PTFE, Neoprene, Hard Rubber, EPDM, FEP, Polyurethane, PFA |

| Electrode | SUS316L, Hastelloy B, Hastelloy C Titanium, Tantalum, Platinium-iridium |

| Structure Type | Integral type, remote type, submersible type, ex-proof type |

| Ambient Temperature | -20~+60deg C |

| Ambient Humidity | 5-100%RH(relative humidity) |

| Measuring Range | Max 15m/s |

| Conductivity | >5us/cm |

| Protection Class | Ip65(standard); Ip68(optional for Remote Type) |

| Process Connection | Flange (standard), Wafer, Thread, Tri-clamp Etc (optional) |

| Output Signal | 4-20mA/Pulse |

| Communication | Rs485(standard), Hart(optional),Gprs/gsm (optional) |

| Power Supply | Ac220v (can Be Used for Ac85-250v) Dc24v (can Be Used for Dc20-36v) Dc12v (optional), Battery Powere |

| Power Consumption | <20W |

| Alarm | Upper Limit Alarm / Lower Limit Alarm |

| Self-diagnosis | Empty Pipe Alarm, Exciting Alarm |

| Explosion Proof | ATEX |

Electromagnetic flow meter is one of the most popular flow meters. Flange type electromagnetic flow meter has been used for more than 50 years worldwide. It is widely used for all conductive liquids in every industry, such as water, acid, alkali, milk, slurry etc. Since founded in 2005, CBRO has sold more than 600 thousand electromagnetic flow meters to provide the solutions for clients in different work conditions.

Advantages :-

Electromagnetic Flow Meter Advantages and Disadvantages

The main advantages of using electromagnetic flow meter is that it is with no moving parts, no pressure loss and require very less maintenance.

Flange type magnetic flow meter can be made large size range from DN3-DN3000mm and with bi-directional flow measurement. CBRO mag flow meters are with built-in self-diagnosis function and support data record / bluetooth function and various kinds of output signals. Electromagnetic flow meter will be affected if there’s strong magnetic filed in the surrounding environment.

Application :-

Flange Electromagnetic Flow Meter Installation Requirement

Electromagnetic flow meter is widely used in water treatment, food industry, pharmaceutical, petrochemical, paper mill, chemical monitoring etc.

In the metallurgical industry, it is often used to control the flow of cooling water for continuous steel casting, continuous steel rolling, and steel-making electric furnaces;

In the field of water supply and drainage in public utilities, electromagnetic flow meters are often used for the transfer measurement of finished product water and raw water in water plants;

In the pulp process of the paper industry, electromagnetic flow meters are involved in the measurement of the flow of grinding pulp, water, acid, and alkali;

In the coal industry, measuring coal washing and pipeline hydraulic conveying coal slurry.

For food and beverage industries, it is used for beer and beverage filling measurement.

For chemical and petrochemical industries, it is used to measure corrosive liquids, such as acids and alkalis etc

Installation :-

Flange Electromagnetic Flow Meter Installation Requirement

In order to obtain a stable and accurate flow measurement, it is very important that the flow meter is installed correctly in the pipe system.

Do not install the meter near equipment that produces electrical interference such as electric motors, transformers, variable frequency, power cables etc.

Avoid locations with pipe vibrations for example pumps.

Do not install the meter close to pipeline valves, fittings or impediments which can cause flow disturbances.

Place the meter where there is enough access for installation and maintenance tasks.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CBRO |

| Line sizes | 50 mm to 3000 mm |

Electromagnetic Flow measurement has been in use around the world for 50 years and more, as witnessed by the popularity of these meters that continues unabated in virtually all sectors of industry. Electromagnetic Flowmeters can be used to measure all electrically conductive liquids (> 5 µS/cm) with or without solids, e.g. water, wastewater, sludge, slurries, pastes, acids, alkalis, juices, fruit pulp, etc.

Insertion Type Electromagnetic Flowmeter is suitable for the most demanding applications. They are based on Faraday’s law of Electromagnetic Induction. The meter features sensor tube and ball valve assembly.

Salient Features:

- Based on Faraday’s law of electromagnetic induction

- Flow tube sizes 100 mm to 600 mm

- Coil assembly in hermetically sealed welded construction

- Integral or remote transmitter

- Field interchangeable electronics

- High linearity due to characteristic magnetic field

- Absolute zero stability and noise elimination due pulsed DC excitation

Applications:

- Chemical, petrochemical and process industries

- Fertilizer industries

- Pharmaceutical industries

- Sugar, beverage industries

| Business Type | Manufacturer, Exporter, Supplier |

| Accuracy | 2.5% |

| Make | CBRO |

| Model | DIGIMAG250 Series |

| Measuring Pipe Size | DN200-DN3000 |

| Connection | Flange |

| Liner Material | Neoprene/Polyurethane |

| Electrode Material | SS316, TI, TA, HB, HC |

| Structure Type | Remote Type |

| Output Signal | Modbus RTU, TTL electrical level |

| Communication | RS232/RS485 |

| Flow speed range | 0.05-10m/s |

| Protection Class | Converter: IP65 Flow Sensor: IP65(standard), IP68(optional) |

Partially filled pipe electromagnetic flow meter is a kind of volume flow meter. It was specially designed for partially filled pipe. It can measure liquid volume from 10% level of the pipe to 100% level of the pipe. It’s accuracy can reach to 2.5%, very accurate for irrigation and waste water liquid measurement. It use remote LCD display so users can read the flow measurement easily. We also provide solar power supply solution for some remote areas where has no power supply.

Advantages :-

Partially filled pipe electromagnetic flow meter Advantages & Disadvantages

Partially filled pipe electromagnetic flow meter can measure partially filled pipe liquid flow, it is very popular in irrigation.

Its can use solar power supply, this type is very suitable for remote areas where has no industrial power supply.

It adopts safe and durable material, service life is longer than normal products. Normally, it can work at least 5-10 years or longer.

We use an accurate mini ultrasonic level meter for its liquid level measurement then the flow meter will record the liquid use this parameter to measure liquid flow.

Application :-

Partially filled pipe electromagnetic flow meter can measure water, waste water, paper pulp, etc. We use rubber or polyurethane liner on it, so it can measure most of none corrosive liquid. It is mainly used in irrigation, water treatment, etc.

It withstand -20-60 deg C media temperature, and it was very durable and safe.

Installation :-

Partially Filled Pipe Electromagnetic Flow Meter Installation and Maintainance

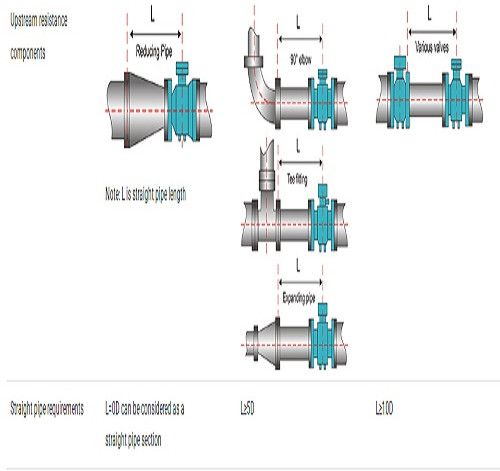

1.Installation Partially filled electromagnetic flow meter should be installed correctly to ensure good measurement. Normally we need leave 10D(10 times of diameter) straight pipe distance before partially filled pipe electromagnetic flow meter and 5D behind partially filled pipe electromagnetic flow meter. And try to avoid elbow/valve/pump or other device which will influent the flow speed. If the distance is not enough, then please install flow meter according to follow picture.

2.Maintenance Routine maintenance: only need to make periodic visual inspections of the instrument, check the environment around the instrument, remove dust and dirt, ensure that no water and other substances enter, check whether the wiring is in good condition, and check whether there are newly installed strong electromagnetic field equipment or newly installed wires near the instrument Cross-instrument. If the measuring medium easily contaminates the electrode or deposits in the measuring tube wall, it should be cleaned and cleaned regularly. 3.Fault finding: if the meter is found to work abnormally after the flow meter has been put into operation or normal operation for a period of time, the external conditions of the flow meter should be checked first, such as whether the power supply is good, whether the pipeline is leaking or in a state of partial pipe, whether there is any in the pipeline Whether air bubbles, signal cables are damaged, and whether the output signal of the converter (that is, the input circuit of the subsequent instrument) is open. Remember to dismantle and repair the flow meter blindly. 4.Sensor inspection 5.Converter check

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CBRO |

| Line sizes | 15 mm to 1000 mm |

| Nominal dia (mm) | 10 to 1000 |

| Working pressure (kg/cm2) | 10, 16, 25, 40 |

| Working temperature | Up to 55oC |

| Electrode material | SS 316L Std.* |

| Sensor lining | Std. Rubber* |

| Display version | Integral/Remote |

| Measuring tube material | SS 304 Std.* |

| Sensor housing material | Std. CS* |

| End connection | Flange/Wafer/Tri-clamp/SMS |

| Flange standard | ANSI 150* |

| Measuring range | 0.2 to 12 m/sec. Bidirectional |

| Accuracy % of measured value | ±O.5% |

| Repeatability | ±0.2% of Span |

| Display | LCD |

| Display units | All standard engineering units in m3, litre, gallon, ft3, imperial gallon |

| Output | Output |

| Power supply | Battery powered (5 years’ battery life) |

| Protection class for sensor | Std. IP 65 Option IP 67/IP 68 for flow tube in remote type |

| Protection class for transmitter | IP 67 |

| Cable length for remote | Std. 10 m* |

| Installation | Inline flanged type |

Adept POWERMAG2500 Full Bore Electromagnetic Flowmeter is a battery Powered Electromagnetic Flowmeter. It is mostly used in the applications where Electric Supply is not available and accurate Flow measurement is essential. The battery powers the Flowmeter for minimum 5 years. AMR Facility like GSM or GPRS is available in the Model. We offer Water Flow Meters with high accuracy rate. Suitable for all types of conductive fluids and water and waste water applications. Measure the rate of flow of slurries or conducting liquids flowing in closed pipes.

Salient Features:

- Based on Faraday’s law of electromagnetic induction

- Flow tube sizes 10 mm to 3000 mm and above

- Coil assembly in hermetically sealed welded construction

- Integral or remote transmitter

- Field interchangeable electronics

- High linearity due to characteristic magnetic field

- Absolute zero stability and noise elimination due pulsed DC excitation

- High long-term stability and reliability

Applications:

- Chemical, petrochemical and process industries

- Fertilizers industries

- Pharmaceutical industries

- Food and drug industries

- Sugar, beverage industries

- Paper and pulp industries

- Water and waste water management

- Dredging industries

- Mining industries

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Make | CBRO |

| Model | DIGIMAG250 Series |

| Size | DN15MM-DN200MM |

| Nominal Pressure | 1.6Mpa |

| Accuracy | ±0.5%(standard) ±0.3% or ±0.2%(optional) |

| Liner | FEP, PFA |

| Electrode | Sus316l, Hastelloy B, Hastelloy C, Titanium, Tantalum, Platinum-iridium |

| Structure Type | Integral Type, Remote Type, Submersible Type, Ex-proof Type |

| Ambient Humidity | 5~90%RH(relative humidity) |

| Measuring Range | Max 15m/s |

| Conductivity | >5us/cm |

| Protection Class | IP65(Standard); IP68(Optional for remote type) |

| Output Signal | 4-20mA pulse frequency relay |

| Communication | Modbus Rtu Rs485, Hart(optional), Gprs/gsm(optional) |

| Power Supply | AC220V(Can be used for AC85-250V) DC24V(Can be used for DC20-36V) DC12V(Optional),Battery Powered 3. |

| Power Consumption | <20W |

| Explosion Proof | ATEX Exdll T6Gb |

Tri-clamp electromagnetic flow meter is a kind of volume flow meter. Tri-clamp electromagnetic flow meter is made of stainless steel, which can be easily disassembled and cleaned quickly, so it is not easily polluted during use, and can effectively prevent the accumulation of measuring fluid residues in the measuring tube.

Wafer electromagnetic flow meter working: The product is based on Faraday’s law of electromagnetic induction, used to measure the conductance greater than 20 μS/cm volume of conductive liquid flow. In addition to measuring the general volume of conductive liquid flow, but also can be used to measure strong acid, alkali and other strong corrosive liquids and mud, pulp, etc.

Advantages :-

Tri-clamp Electromagnetic Flow Meter Advantages and Disadvantages:

Tri-clamp electromagnetic flow meter is easy to be installed and dismantled. It adopts Harmless food grade stainless steel as raw material, so it can touch with food directly.

Stainless steel material has long service life, and SS316 is a kind of anti-corrosive stainless steel, so it can be used to measure most of drinks. It has small size and light weight so it can save your freight fee.

It has multiple output signals for choose. It has current output and pulse output for connecting with PLC or other devices. And you can also read flow measurement by RS485/HART/Profibus.

Application

Tri-clamp electromagnetic flow meter is mainly used in drinking water, milk, ground water, beer, wine, jam, juice and other food & drink industries. It is also widely used in paper pulp, gypsum slurry because it can be cleaned easily.

It adopts harmless stainless steel material so it can measure food directly. And it can withstand high temperature steam disinfection.

Local display type can withstand -20-60 deg C temperature, remote display can withstand -20-120 deg C

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Make | CBRO |

| Model | DIGIMAG250 Series |

| Size | DN25MM-DN200MM |

| Nominal Pressure | 1.6Mpa |

| Accuracy | PTFE, FEP, PFA |

| Electrode | SUS316L, Hastelloy B, Hastelloy C, Titanium, Tantalum, Platinum-iridium |

| Structure Type | Integral type, remote type, submersible type, ex-proof type |

| Ambient Temperature | -20~+60degC |

| Ambient Humidity | 5~90%RH(relative humidity) |

| Measuring Range | 0.5m/s-15m/s |

| Conductivity | >5us/cm |

| Protection Class | IP65(Standard); IP68(Optional for remote type) |

| Output Signal | 4-20mA, pulse/frequency, relay |

| Communication | MODBUS RTU RS485, HART(Optional), GPRS/GSM(Optional) |

| Power Supply | AC220V(Can be used for AC85-250V) DC24V(Can be used for DC20-36V) DC12V(Optional),Battery Powered 3. |

| Power Consumption | <20W |

| Explosion Proof | ATEX Exdll T6Gb |

Wafer electromagnetic flow meter is a kind of volume flow meter. It uses a new generation of special high-quality lining technology and a special mirror-polished PFA lining, which is especially suitable for the measurement of viscous pulp and gypsum slurry. Its detachable electrode makes maintenance more convenient. Principle of Wafer electromagnetic flow meter : The product is based on Faraday’s law of electromagnetic induction, conductance greater than 20 μS/cm volume of conductive liquid flow. In addition to measuring the general volume of conductive liquid flow, but also can be used to measure strong acid, alkali and other strong corrosive liquids and mud, pulp, etc.

Advantages :-

Wafer Electromagnetic Flow Meter Advantages and Disadvantages

Wafer electromagnetic flow meter has short body, it can be installed in narrow areas such as well, ditch, irrigation pipe, etc.

It matches all flanges like ANSI, DIN, JIS, etc. So if you don’t know the flange standards, you can choose this type.

And wafer electromagnetic flow meter adopts harmless and durable stainless steel as raw material(SS304 or SS316), so it can be used for drinking water, underground water, etc. For food grade measurement, we suggest customer use SS316 material.

Wafer electromagnetic flow meter is easy to delivery, save your freight fee. Not only its body is short and thin, but its weight is also very light.

Application

Wafer Electromagnetic Flow Meter Application

Electromagnetic flow meter is widely used in water treatment, food industry, pharmaceutical, petrochemical, paper mill, chemical monitoring etc.

In the metallurgical industry, it is often used to control the flow of cooling water for continuous steel casting, continuous steel rolling, and steel-making electric furnaces;

In the field of water supply and drainage in public utilities, electromagnetic flow meters are often used for the transfer measurement of finished product water and raw water in water plants;

In the pulp process of the paper industry, electromagnetic flow meters are involved in the measurement of the flow of grinding pulp, water, acid, and alkali;

In the coal industry, measuring coal washing and pipeline hydraulic conveying coal slurry.

For food and beverage industries, it is used for beer and beverage filling measurement.

For chemical and petrochemical industries, it is used to measure corrosive liquids, such as acids and alkalis etc.

Installation :-

Wafer Electromagnetic Flow Meter Installation & Maintainance

1. Installation

First of all, we need choose a pair of matching flanges. Then connect the flow meter with pipeline.

Wafer electromagnetic flow meter should be installed correctly to ensure good measurement. Normally we need leave 10D(10 times of diameter) straight pipe distance before wafer electromagnetic flow meter and 5D behind wafer electromagnetic flow meter.

And try to avoid elbow/valve/pump or other device which will influent the flow speed. If the distance is not enough, then please install flow meter according to follow picture.

2. Maintenance

Routine maintenance: only need to make periodic visual inspections of the instrument, check the environment around the instrument, remove dust and dirt, ensure that no water and other substances enter, check whether the wiring is in good condition, and check whether there are newly installed strong electromagnetic field equipment or newly installed wires near the instrument Cross-instrument. If the measuring medium easily contaminates the electrode or deposits in the measuring tube wall, it should be cleaned and cleaned regularly.