| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

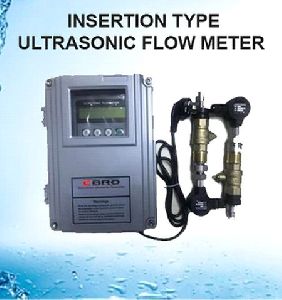

| Make | CBRO |

| Model | TMF1600 Series |

| Click to view more | |

Product Details

Insertion type thermal gas mass flow meter is one of kind mass flow meter which. Is popular in industrial applications is the way they are designed and built. The feature is no moving parts, nearly unobstructed straight through flow path, require no temperature or pressure corrections and retain accuracy over a wide range of flow rates. Straight pipe runs can be reduced by using dual-plate flow conditioning elements and installation is very simple with minimal pipe intrusions. Insertion type thermal gas mass flow meter size from DN40~DN2000mm.

Advantages :-

Insertion type thermal gas mass flow meter advantanges :

(1)Wide range ratio 1000:1;

(2)Large diameter, low flow rate, negligible pressure loss;

(3)Direct mass flow measurement without temperature and pressure compensation;

(4)Very sensitive for low flow rate measurement;

(5)Easy to design and select, easy to install and use;

(6)Suitable for all kinds of single or mixed gas flow measurement Could measure gas with flow velocity from 100Nm/s to 0.1Nm/s, which can be used for gas leak detection;

(7) No pressure loss or very small pressure loss.

Application :-

Insertion type thermal gas mass flow meter application:

Thermal gas air flow meter widely use for Electric power,water treatment,Petrochemical industry,Glass,Ceramics and Building materials industry,and mainly be used to meausre Dry gas,such as Air,Natural gas,LPG gas,Biogas,ect.But thermal gas mass flow couldn’t be used to measure Vapour, Humidity gas and Ethyne.

Installation :-

Insertion type thermal gas mass flow meter installation:

① Regardless of whether the flowmeter is installed vertically or horizontally, keep the flowmeter in a horizontal state.

② In situations where accidental gas stop or accidental gas stop will inevitably cause major irreversible losses, bypass must be installed.

③ There should be at least a 10D straight pipe section in the front of the flowmeter and a 5D (D is the pipe diameter) straight pipe section at the rear.

④ If the instrument is installed outdoors, a sunshade should be added to avoid the sun and rain.

⑤ Make sure that there is no strong magnetic field, strong electric field and strong mechanical vibration near the flowmeter.

⑥ The static grounding of the flowmeter should be reliable, but it cannot be shared with strong current grounding.

⑦ The surrounding environment should confirm that there is no corrosive effect on aluminum alloy.

⑧ Ensure that the gas flow direction is consistent with the arrow direction on the flowmeter.

⑨ Welding operations are prohibited in an explosive environment.

Insertion type thermal gas mass flow meter maintenance:

In the daily operation of the thermal gas mass flowmeter, check and clean the flowmeter, tighten the loose parts, find and deal with the abnormality of the flowmeter in operation in time, ensure the normal operation of the flowmeter, reduce and delay the wear of components, Extend the service life of the flowmeter. Some flowmeters will become fouling after being used for a period of time, and it must be cleaned by pickling etc. depending on the degree of fouling

Looking for "Insertion Thermal Mass Flow Meter" ?

Explore More Products